Computer numerical control (CNC) machining is a specialized manufacturing process that uses computer technology to guide equipment. This makes it possible to automate production processes and increase the volume of production in industrial facilities. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

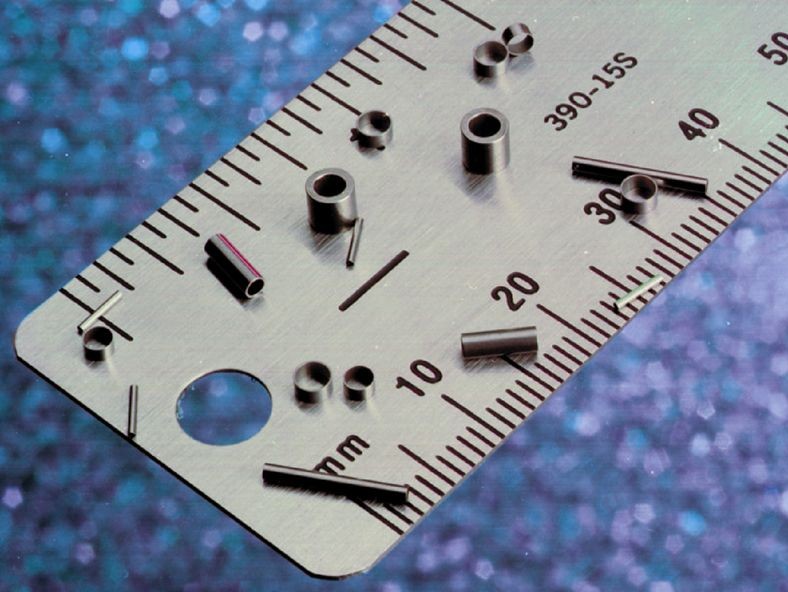

CNC Machining of high precision commercial grade parts for the electronics industry. We sell high precision Commercial Grade CNC Machine Parts. Such as Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, and 4 Axis CNC Machining. CNC Lathe and Swiss Screw Machine parts range in size from .020” to 9.0" diameter. CNC Mill parts fit within one square foot...

At JS Precision Technology, we specialize in CNC machining with a sharp focus on precision, consistency, and speed. Our team brings together deep technical knowledge and advanced equipment to produce high-tolerance components for a wide range of industries, from aerospace and automotive to electronics and medical. We thrive on complexity—transforming challenging blueprints into reality with...

At Associated MetalCast, we specialize in precision CNC machining, delivering high-quality components that meet the exacting standards of today’s industries. With decades of experience and a commitment to innovation, we bring complex designs to life with speed, accuracy, and consistency. Our state-of-the-art machining centers allow us to handle everything from short-run prototypes to full-scale ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Machining Companies

What are the Benefits to CNC Machining?

Answer: CNC (Computer Numerical Control) machining offers numerous benefits, making it a cornerstone of modern manufacturing and a key driver in industrial automation.

First, CNC precision is unmatched. CNC machines follow digital blueprints with tolerances as tight as 0.0001 inches, ensuring consistent, high-quality parts—crucial for industries such as aerospace, defense, medical device manufacturing, and automotive sectors where errors and inconsistencies simply aren’t an option. This extraordinary accuracy stems from precise computer control, virtually eliminating human error common in manual machining and manual milling.

Second, CNC efficiency boosts productivity at every stage. Once programmed, CNC machines can run 24/7 with minimal operator oversight, dramatically reducing lead times compared to traditional manual methods. For example, a complex aerospace or automotive part that once took hours to craft by hand can now be produced in minutes. Automation enables batch production—think thousands of identical components—with zero compromise in quality and repeatability, making CNC manufacturing the backbone of high-volume production.

Third, CNC versatility shines. CNC machines are capable of working with a wide variety of materials, including metals (aluminum, steel, titanium, brass), plastics (ABS, nylon, PVC), composites, and even wood. Multi-axis machining (3, 4, or 5-axis CNC) enables the manufacture of parts with complex geometries, intricate curves, and deep cavities that manual tools simply cannot replicate. This flexibility is vital for sectors requiring complex part design, such as robotics, electronics, and advanced prototyping.

Fourth, cost-effectiveness emerges over time. While the initial setup costs—including programming, tooling, and machine acquisition—may be higher, per-unit costs decrease dramatically in larger production runs due to the repeatability and reduced labor overhead. CNC machines optimize material usage, minimizing waste and scrap rates, which results in substantial resource savings for manufacturers.

Finally, CNC machining significantly enhances workplace safety. Operators manage machines remotely through advanced software, reducing direct exposure to hazards such as spinning tools, sharp chips, or high-speed cutting fluids. Modern CNC machines are built with safety enclosures, emergency stop mechanisms, and real-time monitoring systems.

Industry data supports these claims: a 2023 Manufacturing Institute report noted CNC adoption slashed average production times by 30%. From rapid prototyping and small-batch runs to full-scale mass production, CNC machining delivers the precision, speed, and operational flexibility that manufacturers need to stay competitive in today’s fast-paced markets. Curious about CNC applications in your industry or for your specific project? Ask us for a tailored CNC machining solution!

What is CNC Machining?

CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process that employs computer-controlled machine tools—such as CNC mills, CNC lathes, and CNC routers—to create highly precise and complex parts from virtually any material. The process utilizes specialized software programmed with G-code, which enables precise control over parameters like cutting speed, spindle movement, tool location, feed rate, and tool path. This advanced technology is a significant improvement over traditional manual machining methods, providing greater accuracy, reliability, and repeatability.

Key Benefits of CNC Machining Processes

1. Precision and Accuracy: CNC machining excels in delivering unparalleled precision and accuracy through its computer-controlled automation, consistently producing repeatable results. Modern CNC equipment maintains extremely tight tolerances—often within fractions of a millimeter or even microns—substantially reducing human error and ensuring precise dimensions and complex geometries. The integration of advanced positioning systems, multi-axis capabilities, and digital feedback mechanisms further enhances precision. Rigorous quality assurance practices, such as in-process inspections and post-machining measurements, confirm the accuracy of components. This level of precision is essential in sectors that demand reliability and functionality, such as aerospace, automotive, electronics, robotics, and medical device industries.

2. Increased Efficiency: CNC machining transforms modern manufacturing by automating processes, allowing machines to operate continuously with minimal manual oversight. This leads to uninterrupted production cycles and optimal machine utilization. Automation speeds up production, enabling faster time-to-market and reducing lead times for both prototyping and large-scale manufacturing. Quick changeover and flexible CNC programming minimize downtime between part runs, ensuring smooth transitions across projects. By handling multiple operations simultaneously and automatically adjusting cutting parameters, CNC machines streamline production, reduce potential errors, and minimize costly rework. The result? Faster delivery, higher throughput, and significant cost control.

3. Repetitive Operations: CNC machining is ideal for repetitive manufacturing tasks, delivering consistent quality and precise dimensions even over long production runs. Machines follow programmed instructions to produce identical parts every time, ensuring uniform outcomes crucial for industries like automotive, defense, and consumer electronics. CNC machines maintain accuracy at high speeds and can operate continuously without the need for frequent manual intervention. Built-in quality control, including in-process inspections and automated measurement systems, ensures reliable and repeatable results.

4. Versatility: CNC machining is a powerhouse of flexibility and adaptability. Capable of processing an extensive array of materials—metals, plastics, composites, and wood—CNC machines empower manufacturers to select the ideal substrate for each application. This versatility is crucial for diverse industries, from automotive and aerospace to electronics, medical, defense, and even custom furniture manufacturing.

Beyond material flexibility, CNC machining handles everything from single prototypes to high-volume production. It creates customized parts with intricate features and efficiently produces large batches of components. CNC technology also accommodates secondary processes such as surface finishing, heat treatment, engraving, polishing, and assembly, consolidating manufacturing steps and reducing lead times.

5. Ability to Create Complex Geometries: CNC machining stands out for producing intricate, complex shapes and features that would be nearly impossible with manual machining. Multi-axis CNC machines (3-, 4-, and 5-axis) enable 3D contouring, undercuts, deep cavities, and compound angles. Advanced CAD/CAM software integration allows designers to create detailed 3D models that are translated directly into precise machining instructions. Adaptive tooling and advanced toolpath strategies tackle the most challenging geometries, making CNC ideal for aerospace, medical implants, mold making, and custom electronics.

6. Customization and Rapid Prototyping: CNC machining is highly customizable, making it ideal for rapid prototyping, iterative product development, and one-off parts. By simply updating the machine’s programming, manufacturers can rapidly switch between different part designs or make on-the-fly adjustments to accommodate late-stage design changes. This responsiveness supports faster innovation cycles, enabling businesses to adapt to evolving market demands and customer requirements.

7. Enhanced Safety: CNC machining significantly boosts workplace safety. Operators interact with machines primarily through computer interfaces, drastically reducing physical proximity to potentially hazardous moving parts, cutting tools, and flying debris. Safety features—such as emergency stop buttons, protective enclosures, and interlock systems—are standard on modern CNC equipment. Advanced monitoring systems detect tool wear or failures early, minimizing the risk of accidents and ensuring a safer work environment.

8. Lower Error Rate: CNC machining dramatically reduces the error rate compared to manual machining. Once programmed, CNC machines follow instructions exactly, minimizing mistakes from human factors like fatigue, distraction, or inconsistency. Automated control ensures consistent and repeatable results, while built-in checks and real-time feedback allow for instant error detection and correction. This leads to higher product quality and less costly rework or material scrap, boosting overall manufacturing productivity and customer satisfaction.

9. Time and Cost Savings: CNC machining reduces both time and costs throughout the manufacturing process. Automated operation minimizes manual labor, enhances throughput, and accelerates production cycles. Optimized cutting parameters reduce material waste, while precise control and integrated quality checks eliminate the need for time-consuming corrections and rework. CNC’s ability to efficiently handle complex part designs further reduces production costs, making it a cost-effective solution for both small businesses and large-scale manufacturers.

CNC machining brings unmatched precision, efficiency, and adaptability to the manufacturing process, driving up productivity, quality, and cost savings. Its capacity to handle intricate designs and various materials makes it a cornerstone technology in today’s manufacturing landscape. Ready to explore how CNC machining can transform your production workflow? Contact us for a free CNC project consultation!

CNC Applications

CNC machining is a versatile technology that empowers manufacturers to craft components across nearly every industry with exceptional precision and efficiency. From industrial mass production to custom prototyping, CNC technology enables the creation of high-quality, consistent, and reliable parts with intricate features and durable materials.

Major industries and common CNC machining applications include:

- Metalworking: CNC machining produces dies, molds, coinage dies, fittings, gears, shafts, and complex mechanical assemblies. It is fundamental in manufacturing machine tool parts, tooling, and equipment for sectors such as heavy machinery and industrial automation.

- Woodworking: CNC routers and mills cut, engrave, and shape wood for custom furniture, cabinetry, decorative moldings, musical instruments, and architectural components.

- Automotive Manufacturing: CNC machining is used for engine parts, transmission components, chassis elements, trim pieces, suspension systems, and performance upgrades, ensuring tight tolerances and repeatable quality for both OEM and aftermarket parts.

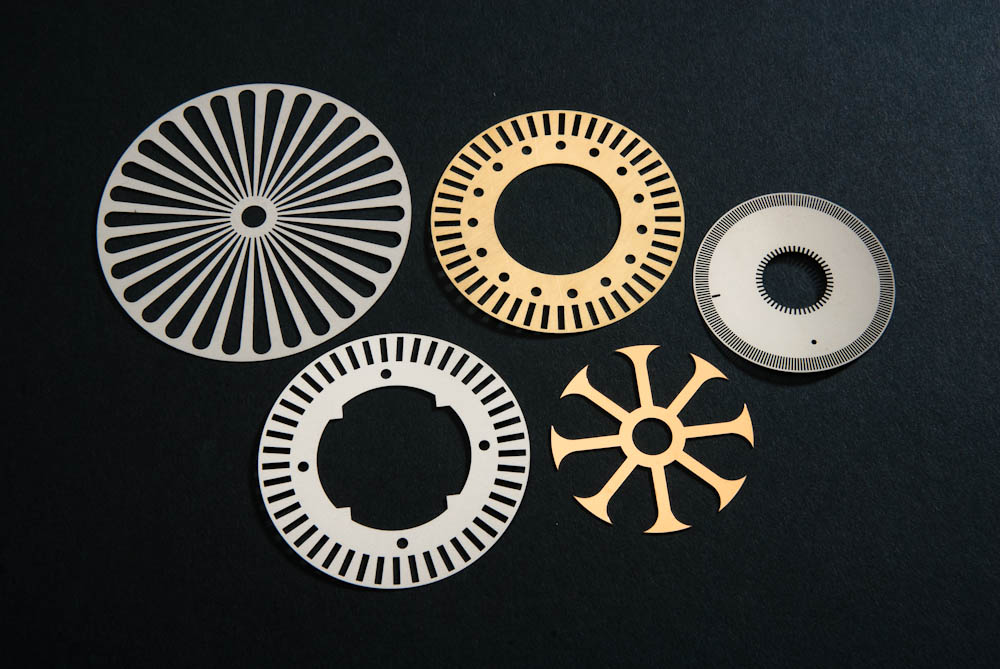

- Electronics: CNC machines fabricate circuit boards (PCBs), connectors, heatsinks, enclosures, and intricate device housings, supporting the miniaturization and reliability of modern electronics.

- Aerospace Engineering: CNC is indispensable for manufacturing ground support equipment, compressor cases, control panels, instrument housings, jet engine components, and structural airframe parts, where safety and precision are paramount.

- Energy Sector: CNC machining creates solar panel frames, gear cases, couplings, wind turbine components, and fluid manifold blocks for oil, gas, and renewable energy applications.

- Medical Device Manufacturing: CNC processes are used for spinal fusion cages, orthopedic implants, bone plates, surgical tools, dental devices, and custom prosthetics, meeting stringent regulatory standards for safety and hygiene.

- Marine Industry: CNC machining enables the creation of propulsion systems, connecting shafts, custom valves, and corrosion-resistant fittings for marine vessels and offshore structures.

- Military and Defense: CNC manufacturing supports production of missile components, aircraft seat frames, precision mounts, weapons systems, and munitions hoists, where reliability and consistency are mission-critical.

- Consumer Goods: CNC is used for manufacturing household fixtures, appliance housings, sporting goods, and custom hardware with high finish quality.

In addition, CNC technology extends to producing a wide range of specialized items, including ball joints, valve bodies, computer assemblies, semiconductor parts, suspension arms, thermal management devices, spindle housings, fasteners, switch gears, module blocks, and more. The adaptability and scalability of CNC machining make it an indispensable tool for innovation and reliability in modern manufacturing.

What is the History of CNC Machining?

The history of CNC (Computer Numerical Control) machining is a fascinating journey of technological evolution and industrial innovation, spanning more than a century.

Early Beginnings: Pre-CNC Automation (1800s–1940s)

CNC’s roots trace back to the Industrial Revolution. In the early 1800s, machine tools like lathes and mills were operated manually. The concept of programmed automation emerged in 1801 with Joseph Marie Jacquard’s punch-card loom, which inspired future developments in automated manufacturing. By the 1840s, engineers used cams and templates to guide machines, setting the stage for numerical control. World War II (1939–1945) accelerated innovation, as the U.S. military required faster, more precise production of aircraft parts—leading to early ideas in automation and process control.

Birth of Numerical Control (1940s–1950s)

The modern CNC story begins with John T. Parsons, an engineer at Parsons Corp, who, in 1947, envisioned controlling machine tools using punched cards. Working with MIT’s Servomechanisms Laboratory, Parsons helped develop the first numerically controlled (NC) milling machine by 1949, which used punched tape to direct movements. In 1952, MIT publicly demonstrated this machine, cutting a helicopter rotor blade with unprecedented precision. Richard Kegg further refined NC technology at Cincinnati Milacron, leading to the commercial release of the “Hydrotel” NC machine in 1955.

Enter Computers: CNC Emerges (1960s–1970s)

Early NC machines relied on hardwired logic and magnetic tape, limiting their flexibility. The shift to true CNC occurred with the advent of digital computers in the 1960s. By 1967, manufacturers like Kearney & Trecker introduced machines with integrated circuits, enabling digital programming. The 1970s saw the introduction of microprocessors—such as Intel’s 4004 in 1971—making CNC machines more compact, affordable, and powerful. The parallel development of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, pioneered by Patrick Hanratty’s PRONTO in 1961, revolutionized design-to-manufacturing workflows.

Mainstream Adoption (1980s–1990s)

During the 1980s, CNC machining entered mainstream manufacturing. Falling computer costs and the rise of user-friendly interfaces from companies like Fanuc enabled widespread adoption, even among small and medium-sized shops. Multi-axis CNC machines (3-, 4-, and 5-axis) became standard for tackling the intricate geometries demanded by aerospace, automotive, and electronics industries. By 1989, over 25% of U.S. machine shops had adopted CNC technology, according to the National Institute of Standards and Technology. Industry-standard G-code, developed by the Electronic Industries Alliance in the 1960s, became the universal language of CNC programming.

Modern Era (2000s–Present)

Since 2000, CNC machining has advanced rapidly with high-speed machining, hybrid additive-subtractive processes, and connectivity via the Industrial Internet of Things (IIoT). The emergence of desktop CNC machines (e.g., ShopBot, Tormach) has democratized high-precision manufacturing for startups, makers, and educational institutions. By 2023, the global CNC market reached $85 billion, fueled by demand in electronics, medical, and energy sectors (Grand View Research). Today, artificial intelligence, machine learning, and real-time monitoring are pushing the boundaries of precision, efficiency, and automation, with industry leaders like Haas Automation and DMG MORI setting new standards for performance and integration.

From punched cards to cloud-connected, AI-driven smart factories, CNC machining’s evolution reflects the relentless pursuit of accuracy, scalability, and speed—transforming manufacturing and supply chains worldwide.

CNC Machining Service Details

CNC machining services provide professional, turnkey manufacturing solutions using computer-controlled machines to fabricate precise, custom parts to exact client specifications. These services encompass every stage of the process, from material selection and digital programming to finishing, assembly, and logistics.

Material Selection:

CNC manufacturers work with a broad array of materials, including metals (aluminum, steel, brass, titanium), plastics (ABS, PVC, nylon, polycarbonate), composites, and wood. The choice of material depends on the specific application, mechanical properties required, environmental resistance, and part functionality.

Design and Programming:

Clients typically provide design specifications in the form of 2D engineering drawings, 3D CAD models, or digital files. CNC service providers optimize these designs for manufacturability, advising on material suitability, achievable tolerances, and the best machining approaches. Designs are then translated into machine-readable instructions via advanced computer-aided manufacturing (CAM) software, such as Mastercam or Fusion 360.

Machining Operations:

The CNC machining process begins with setting up the machine—installing cutting tools, fixtures, and workholding devices. The programmed instructions are uploaded, and the machine executes operations such as CNC milling, turning, CNC drilling, grinding, and precision cutting. Multi-axis CNC machines are capable of producing complex geometries, intricate features, and high-volume part runs with minimal manual intervention.

Quality Control:

Stringent quality control is standard practice in CNC machining services. This includes in-process inspections, dimensional checks, and the use of advanced metrology equipment (e.g., coordinate measuring machines, laser scanners). Inspection reports and certificates of conformance validate compliance with customer and industry standards.

Finishing and Secondary Processes:

After machining, parts may undergo additional processes to meet functional or aesthetic requirements. Common finishing options include anodizing, plating, powder coating, painting, deburring, polishing, laser engraving, and assembly. Such processes enhance corrosion resistance, durability, and appearance.

Packing and Logistics:

Parts are carefully packaged to ensure safe transit and delivered via flexible shipping options, including expedited and international freight. Leading CNC service providers offer tracking, insurance, and custom documentation for global clients.

Communication and Project Management:

Effective collaboration between clients and CNC machining partners is critical. Clear communication on design specs, material needs, tolerances, and delivery schedules ensures project success. Experienced providers offer regular project updates, prompt responses to inquiries, and dedicated technical support.

Why outsource CNC machining? Leveraging specialized CNC machining services enables businesses to tap into advanced manufacturing expertise, reduce capital investment, accelerate project timelines, and achieve production scalability. Request a CNC machining quote today.

CNC Machinery

Diverse types of CNC machinery are used to meet the needs of modern manufacturing:

- Vertical Milling Machines: Utilize cutting tools that move along a vertical axis, capable of cutting or drilling from various angles—front, side, or above. They are typically used for shaping one-dimensional (1D) and two-dimensional (2D) geometries.

- Horizontal Milling Machines: Similar to vertical mills but feature a rotary (universal) table, allowing work at multiple angles. Horizontal mills are more costly but offer greater versatility and precision, especially for complex or multi-sided parts.

- CNC Cutting Machines: Execute cuts with exceptional accuracy, often operating on up to six axes simultaneously for intricate profiles and contours.

- CNC Drilling Machines: Use multiple turrets or spindles for rapid tool changes—sometimes in as little as two seconds—enabling efficient drilling of holes in a variety of materials.

- CNC Lathes and Turning Centers: Rotate workpieces against cutting tools to create cylindrical parts, threads, or tapers. Modern CNC turning machines utilize multiple axes, automated tool changers, and sophisticated G-code programming for complex geometries.

CNC Machining Variations

CNC milling, also known as CNC turning when referring to rotational movement, is a foundational process in modern manufacturing. Precision CNC machining companies offer a range of services, including:

- CNC Milling: Uses rotary cutters to remove material, ideal for engraving, pocketing, slotting, and contouring. Milling machines use various end mills, chamfer mills, and helical mills, and can operate in multiple axes for complex part features.

- CNC Turning: Involves rotating the workpiece against a single-point cutting tool, perfect for producing round parts such as shafts, bushings, and fasteners. Lathes—including turret lathes and engine lathes—are commonly used.

- CNC Drilling: Employs computer-guided machines to bore precise holes of various shapes and sizes using spinning multi-point drill bits. This method is essential in automotive, aerospace, defense, electronics, and many consumer goods industries.

- CNC Grinding: Uses software-controlled abrasive belts, discs, or wheels to finish parts by removing excess material and achieving high surface quality.

- CNC Plasma Cutting: Employs powerful plasma torches or lasers to cut programmed shapes from metal sheets or plates with high accuracy.

Precision CNC machining, driven by precise programming, shapes and cuts workpieces to exact specifications—ideal for industries requiring tight tolerances, such as medical device manufacturing, electronics, and aerospace engineering.

How to Select a CNC Machine Manufacturer?

Selecting a CNC machine manufacturer is a critical business decision that impacts your production capabilities, cost structure, and long-term competitiveness. Here’s a comprehensive guide to help you choose the right CNC equipment partner, updated for 2025:

1. Define Your Requirements

- Assess your intended applications: Will you be milling, turning, drilling, or using multi-axis or hybrid (additive-subtractive) processes?

- Consider material compatibility (metals, plastics, wood, composites), desired part complexity, and production volume.

- Identify must-have features: spindle speed, axis count (3, 4, or 5), automation, and software compatibility (G-code, CAM integration).

2. Evaluate Manufacturer Reputation

- Research company history, customer reviews, and industry awards.

- Leading names like Haas Automation, DMG MORI, Mazak, and Okuma are known for reliability and service. Check recent feedback on industry forums, review sites, and trade publications.

3. Assess Quality and Technology

- Compare machine specs (repeatability, accuracy, speed) and advanced features (IoT integration, AI-driven monitoring, automated tool changers).

- Request case studies or demo runs to evaluate real-world performance and suitability for your industry.

4. Check Support and Service

- Prioritize manufacturers with strong local support networks, spare parts availability, and training resources.

- Confirm warranty length, maintenance costs, and average lead times for repairs or parts.

5. Compare Costs and Value

- Consider both upfront price and long-term ROI (machine reliability, upgrade paths, service costs).

- Request detailed quotes including tooling, software, shipping, and installation.

6. Verify Scalability and Compatibility

- Ensure machines can scale with your business and integrate with existing CAD/CAM systems.

- Check for modular upgrade options and future-proof technologies.

7. Research Local Presence

- Domestic manufacturers may offer shorter lead times, lower shipping costs, and easier access to support. Factor in tariffs and import duties on international purchases.

Things to Consider Regarding CNC Machining

Choosing the right CNC machining partner or equipment is vital for your project’s success. Here are the top factors to evaluate before making a decision:

- Machine Capabilities: Not all CNC shops or machines are created equal. Assess machinery types, axis count, maximum part size, and material compatibility against your project requirements.

- Supplier Experience: Review industry experience, quality certifications (ISO 9001, AS9100), and past project portfolios.

- Volume and Lead Time: Clarify expected order quantity, lead times, and flexibility for repeat or rush jobs.

- Budget and Cost Structure: Obtain detailed quotes, including setup fees, unit pricing, finishing, and shipping costs.

- Delivery and Support: Specify packaging, delivery preferences, and after-sales support requirements.

- Communication: Clear, responsive communication is essential for smooth project execution and issue resolution.

Before contacting suppliers, create a comprehensive list of requirements. Review our vetted CNC machining companies and compare their capabilities. Shortlist three or four candidates, initiate discussions, and evaluate their responsiveness and technical fit. Select the provider that best aligns with your needs and project goals.

What is CNC machining?

CNC machining, or Computer Numerical Control machining, is a precise subtractive manufacturing process in which computer-guided machine tools—such as mills, lathes, and routers—shape complex parts from metal, plastic, composites, or wood. Specialized software, programmed with G-code, controls variables like cutting speed, spindle movement, tool position, feed rate, and paths, ensuring repeatability and accuracy far beyond manual machining methods.

What are the main benefits of CNC machining?

CNC machining delivers exceptional precision, high repeatability, efficiency, and versatility. It easily handles both custom prototypes and high-volume production runs while maintaining tight tolerances and consistent quality. CNC processes reduce human error, waste, and material scrap, streamline production through automation, speed up delivery, enable batch manufacturing, and improve workplace safety. Its programmability allows for rapid design changes and efficient production of complex geometries from many types of materials.

Which industries use CNC machining?

CNC machining is widely used in aerospace, automotive, electronics, medical devices, energy, defense, marine, woodworking, and consumer goods manufacturing. Applications include components such as engine parts, gears, medical implants, circuit boards, molds, tools, housings, precision mounts, and custom fixtures. Its adaptability makes it essential for both mass production and specialized, complex part requirements in diverse sectors.

What types of CNC machines are there?

The major types of CNC machines include vertical and horizontal milling machines, CNC lathes and turning centers, CNC drilling machines, CNC cutting machines, and specialized systems like CNC grinders and plasma cutters. Each is suited for machining different shapes, sizes, and materials to meet specific manufacturing needs.

How do I select a CNC machine manufacturer?

When selecting a CNC machine manufacturer, consider your application requirements, required machine features, and material compatibility. Research company reputation, technology, support services, long-term value, scalability, and local presence. Comparing warranties, after-sales support, spare parts availability, and customer feedback helps ensure the best fit for your operational and financial needs.

What services do CNC machining providers offer?

CNC machining service providers offer turnkey solutions, including material selection, CAD/CAM design support, digital programming, precision manufacturing, quality control, finishing services (such as anodizing or engraving), packing, shipping, and ongoing communication. They assist from concept through finished part delivery while ensuring quality, accuracy, and timely project management.

What factors should I consider when choosing a CNC machining partner?

Key considerations when selecting a CNC machining partner include the types of machines and their capabilities, supplier industry experience and certifications, lead times, cost structure, delivery and after-sales support, and quality of communication. Review detailed quotes and supplier portfolios, confirm responsiveness, and align capabilities with your specific application requirements to ensure project success.

Broaching

Broaching CNC Machining

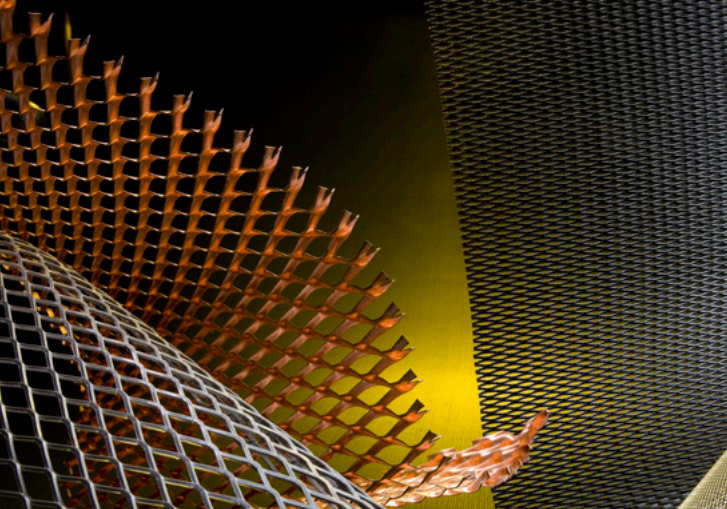

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

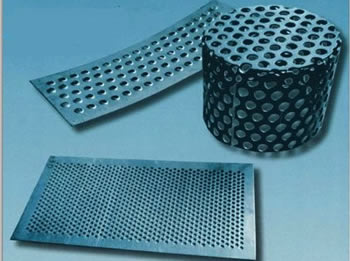

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

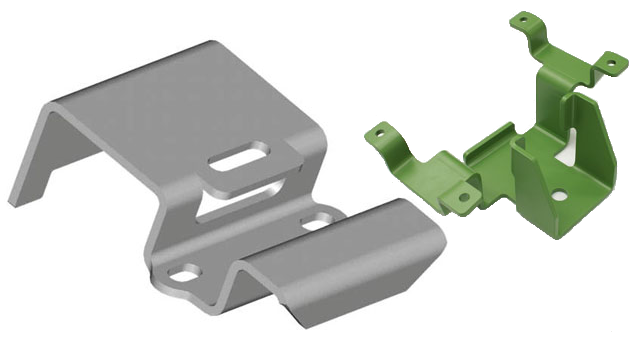

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services