Custom machining is a process whereby materials are machined to meet a customer’s requirements. Custom machining is part of the CNC machining process. In this type of CNC machining process, operators create new parts with the help they get from different forms of CNC machining. Custom machining is utilized when there is a need for a specific part that is not available in a machine shop or when there is a special requirement for a common part. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

CNC Machining of high precision commercial grade parts for the electronics industry. We sell high precision Commercial Grade CNC Machine Parts. Such as Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, and 4 Axis CNC Machining. CNC Lathe and Swiss Screw Machine parts range in size from .020” to 9.0" diameter. CNC Mill parts fit within one square foot...

At JS Precision Technology, we specialize in CNC machining with a sharp focus on precision, consistency, and speed. Our team brings together deep technical knowledge and advanced equipment to produce high-tolerance components for a wide range of industries, from aerospace and automotive to electronics and medical. We thrive on complexity—transforming challenging blueprints into reality with...

At Associated MetalCast, we specialize in precision CNC machining, delivering high-quality components that meet the exacting standards of today’s industries. With decades of experience and a commitment to innovation, we bring complex designs to life with speed, accuracy, and consistency. Our state-of-the-art machining centers allow us to handle everything from short-run prototypes to full-scale ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More Custom Machining Manufacturers

In modern manufacturing, custom machining plays a critical role in producing specialized parts tailored to meet unique requirements. Whether you need to create a single prototype, modify a standard component, or manufacture large parts with complex geometries, custom machining services enable precision and flexibility unmatched by off-the-shelf solutions. This approach is essential for projects demanding exacting tolerances, unique materials, or custom designs that standard suppliers cannot provide. As advanced manufacturing processes continue to evolve, the importance of custom machining in industries such as aerospace, automotive, medical device, and electronics is only increasing.

Why is Custom Machining Necessary?

Custom machining is vital for a range of applications where standard parts do not suffice. Below are key reasons why companies and engineers choose custom machining solutions:

- The required item is not compatible with mass-produced parts or is unavailable from commercial suppliers, necessitating bespoke machining for a perfect fit or function.

- The component must possess unique features—such as specific dimensions, surface finishes, or material properties—that traditional manufacturing processes cannot deliver.

- There is a need to consolidate multiple parts into a single, integrated component to reduce assembly time, improve strength, or minimize potential points of failure.

- In emergency situations, custom machining services can rapidly produce high-quality parts, minimizing downtime and ensuring business continuity.

- When production volumes are low, such as for prototypes, short runs, or one-off parts, custom machining offers a cost-effective alternative to expensive tooling and setup required for mass production.

What is Custom CNC Machining? Step-by-Step Process

Custom CNC machining is an advanced manufacturing technology that leverages computer numerical control (CNC) to automate the creation of highly precise and complex components. Compared to manual machining, CNC machining offers superior accuracy, repeatability, and flexibility, making it the preferred choice for both prototyping and production runs.

If you're curious about how custom CNC machining works or researching the best processes for your project, here’s a detailed breakdown:

- Design and Modeling: The process begins with a computer-aided design (CAD) model created by a design engineer. This digital blueprint specifies all dimensions, tolerances, and surface finishes required for the part.

- CAM Programming: The CAD model is then imported into computer-aided manufacturing (CAM) software. Here, the designer generates detailed tool paths and CNC programs that dictate every movement of the machine tools.

- Machine Setup: The machine operator loads the CNC program into the CNC machine, sets up the raw material (workpiece), and installs the necessary cutting tools.

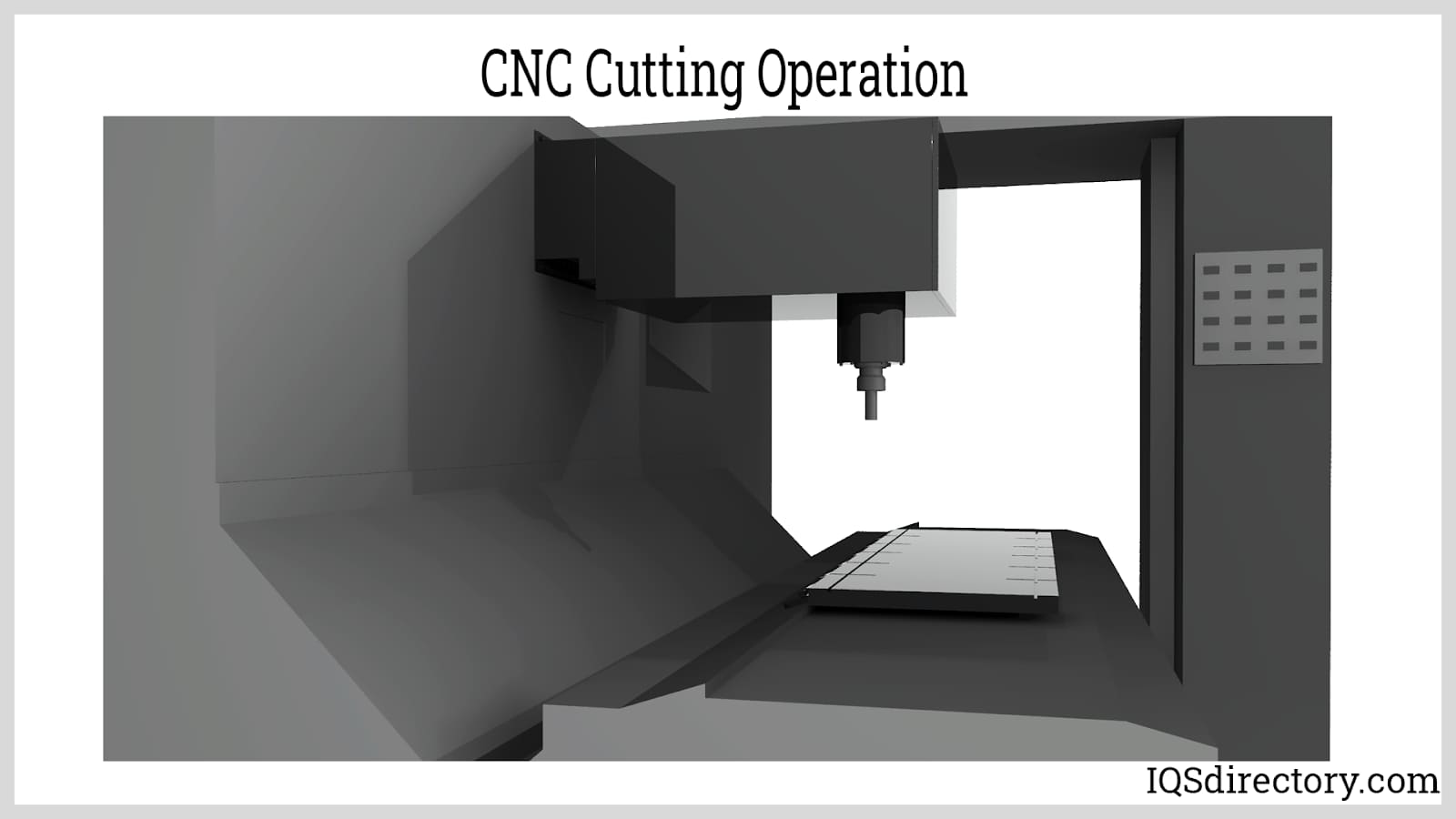

- Machining Operations: The CNC machine executes programmed operations—such as milling, turning, drilling, sawing, broaching, lapping, and honing—to transform the raw material into the final component. These operations are highly automated and controlled to ensure consistent quality.

- Inspection and Quality Assurance: After machining, components are inspected using precision measurement tools and coordinate measuring machines (CMMs) to verify that they meet specifications.

- Finishing Processes: Depending on requirements, parts may undergo additional finishing steps such as surface grinding, anodizing, bead blasting, or painting to enhance appearance and performance.

Types of Custom Machining Services

Custom machining encompasses a wide range of manufacturing services, each suited for different applications, materials, and part geometries. Understanding these options can help you select the right process for your needs. Below are the most common types of custom machining:

CNC Milling

CNC milling is a versatile process used to remove material from a solid block (often called a billet) to create complex shapes, holes, and slots. High-speed rotating cutters move along multiple axes (X, Y, Z) to achieve intricate geometries and tight tolerances. CNC milling is ideal for producing prototypes, custom mechanical parts, enclosures, brackets, and more. It supports a variety of materials, including metals (aluminum, steel, titanium), plastics, and composites. Many traditional milling machines can be retrofitted for CNC operation, further expanding their flexibility for custom machining projects.

Interested in learning more about how CNC milling can benefit your application? Explore our CNC milling resources or request a quote from a qualified provider.

CNC Turning

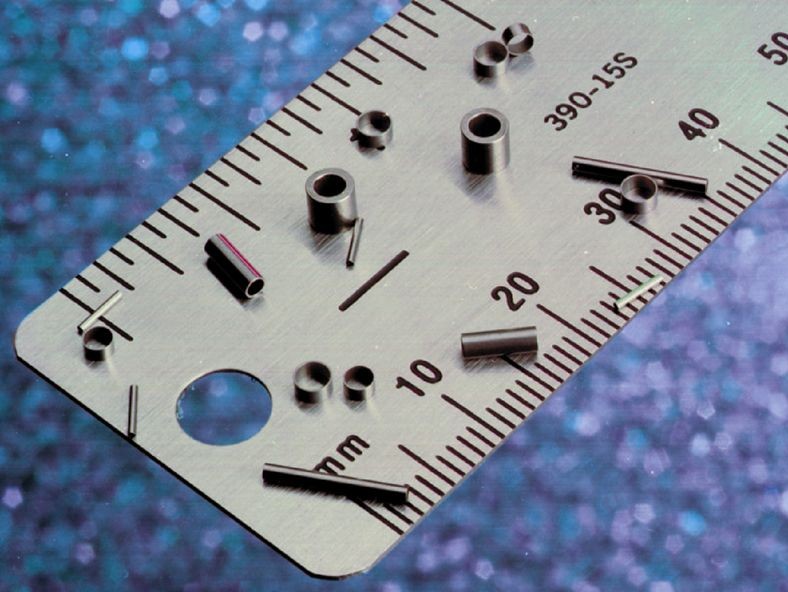

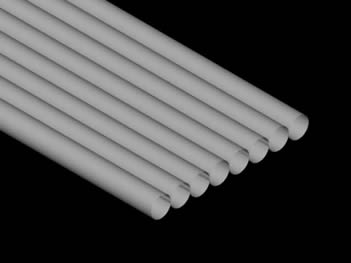

CNC turning is commonly used for producing cylindrical parts such as shafts, bushings, and threaded components. In this process, a metal rod or bar is rotated while a CNC-controlled cutting tool removes material to achieve the desired profile. CNC lathes enable the efficient production of both simple and highly complex 3D shapes, offering superior accuracy compared to manual lathes. Turning processes are often complemented by secondary operations like knurling, threading, or finishing for enhanced performance and appearance. CNC turning is the go-to choice for high-precision parts used in automotive, aerospace, and industrial machinery applications.

Curious about which CNC turning capabilities are best for your project? Discover top CNC turning providers and learn how they address your specifications.

CNC Router

CNC routers are specialized machines designed for cutting, engraving, and shaping large sheets of material such as wood, plastics, composites, foams, glass, and certain metals. They are highly effective for fabricating moldings, frames, furniture, signs, architectural panels, and even musical instruments. CNC routers stand out for their ability to handle oversized workpieces and produce intricate patterns, making them a popular choice for both industrial and hobbyist applications.

Are you looking to streamline your fabrication process with a CNC router? Find CNC router services that match your project scale and budget.

Other Custom Machining Processes

In addition to the core services above, custom machining may involve:

- EDM (Electrical Discharge Machining): For intricate shapes and hard materials, EDM uses electrical sparks to erode material with exceptional precision.

- Surface Grinding: Achieves ultra-smooth finishes and precise flatness for critical applications.

- Broaching & Honing: Used for creating keyways, splines, and fine surface finishes inside holes or slots.

- Waterjet and Laser Cutting: Non-contact methods ideal for heat-sensitive materials and highly detailed profiles.

Applications of Custom Machining

Custom machining is indispensable across a diverse set of industries and use cases. Wondering how custom machining can add value to your business? Here are some common applications:

- Aerospace: Manufacturing precision components for engines, landing gear, structural assemblies, and avionics systems. The industry demands tight tolerances and exotic materials, both of which are well-served by custom CNC machining.

- Automotive: Producing one-off prototypes, performance parts, custom brackets, and engine components for vehicles ranging from race cars to electric vehicles. Rapid prototyping and low-volume production are key buyer intents in this sector.

- Medical Devices: Creating surgical instruments, orthopedic implants, dental devices, and diagnostic equipment. Custom machining ensures biocompatible materials and flawless finishes.

- Electronics: Fabricating enclosures, heat sinks, connectors, and mounting hardware for advanced electronic assemblies.

- Agricultural Equipment: Machining robust, wear-resistant parts for tractors, harvesters, and irrigation systems.

- Construction and Industrial Equipment: Producing heavy-duty components for cranes, earth movers, and industrial automation.

- Energy: Manufacturing precision parts for wind turbines, oil & gas exploration, power plants, and renewable energy systems.

Examples of Finished Parts from Custom Machining

Here are just a few examples of high-value components produced through custom machining:

- Precision surgical equipment and medical instruments

- Custom screws, nuts, and fasteners

- Chassis and frames for automobiles and motorcycles

- Hydraulic system components and fluid connectors

- Engine blocks and turbine parts for aircraft

- Rotating shafts, axles, and gears

- Custom enclosures, brackets, and mounting plates

- Industrial tooling and dies

Need a specific part or assembly not listed here? Contact a custom machining expert to discuss your unique project requirements and receive tailored recommendations.

Benefits of Custom Machining Services

Custom machining offers substantial advantages over conventional manufacturing approaches. The following benefits make it the preferred option for many engineering and procurement teams:

Work with Difficult or Exotic Materials

Some engineering projects require parts made from materials that are challenging to machine, such as hardened steels, titanium, Inconel, ceramics, or specialty plastics. Custom CNC machining enables precise control over cutting speeds, tool selection, and cooling—allowing for successful fabrication where traditional manual machining would fail. This opens up possibilities for advanced applications in aerospace, defense, and medical technology.

Superior Precision, Consistency, and Repeatability

Computer-controlled processes ensure every part produced meets exacting tolerances, regardless of batch size. This is essential for industries where safety, performance, and reliability are paramount. Custom machining providers employ rigorous quality control, statistical process control (SPC), and automated measurement to guarantee every part meets customer specifications.

Rapid Prototyping and Short Lead Times

Custom machining services are ideal for iterative design, prototyping, and new product development. By eliminating the need for costly tooling or molds, companies can quickly test concepts, refine designs, and bring products to market faster. This agility is crucial in competitive industries where speed and innovation drive success.

Cost-Effective for Low-Volume and One-Off Parts

For low-quantity production runs or unique parts, custom machining eliminates the high setup costs associated with mass production methods like injection molding or die casting. This makes it an economical choice for startups, research and development teams, and organizations with specialized requirements.

Customization and Design Flexibility

Custom machining empowers engineers and designers to realize complex geometries, intricate features, and custom finishes that are impossible to achieve with standard manufacturing. This design freedom translates to better product performance, unique aesthetics, and a competitive edge in the marketplace.

Key Factors When Selecting a Custom Machining Provider

Choosing the right custom machining company is critical to the success of your project. Here are important decision factors to consider as you evaluate potential partners:

- Capabilities and Equipment: Does the provider offer the specific machining processes (milling, turning, EDM, etc.) and material expertise you require?

- Experience and Industry Knowledge: Is the company familiar with your industry’s standards, regulations, and common challenges?

- Quality Assurance: What certifications (ISO 9001, AS9100, etc.) and inspection protocols do they have in place to ensure consistent results?

- Lead Time and Turnaround: Can the provider meet your project deadlines and accommodate rush orders if needed?

- Customer Service and Communication: Does the supplier offer responsive support, clear quotes, and detailed project updates?

- Online Reviews and References: What do previous clients say about their work quality and reliability?

- Competitive Pricing: Are their rates transparent and aligned with your budget constraints?

Looking for a seamless way to compare custom machining services? Use our comprehensive directory of custom machining companies to review business profiles, capabilities, and customer testimonials. Each custom machining company profile includes detailed information about their equipment, expertise, and a convenient contact form for requesting quotes or more details.

Getting Started: How to Order Custom Machined Parts

If you're ready to source precision components or have questions about the custom machining process, follow these steps to get started:

- Define your project requirements, including material, geometry, tolerances, and desired quantities.

- Prepare a CAD drawing or technical specification for your part. Unsure where to start? Many custom machining providers offer design assistance and manufacturability reviews.

- Research and shortlist potential machining companies using our custom machining directory.

- Submit a request for quote (RFQ) form to multiple suppliers. Be sure to include drawings, material specs, and project timelines for accurate pricing and lead times.

- Evaluate proposals, ask clarifying questions, and request samples or references as needed.

- Select the partner who best matches your technical, quality, and budgetary needs.

Ready to take the next step? Request a custom machining quote today or connect with an expert for a free consultation.

Frequently Asked Questions About Custom Machining

Below are common questions buyers and engineers have when exploring custom machining services:

- What materials can be used in custom machining? — Most metals (aluminum, steel, titanium, brass, copper), plastics (acrylic, Delrin, nylon), and composites can be machined. Exotic and hard-to-machine materials are also supported by advanced CNC machining centers.

- How accurate is CNC custom machining? — Tolerances as tight as ±0.001" (25 microns) are achievable, with even finer precision possible for certain applications.

- What is the typical turnaround time for custom machined parts? — Turnaround varies by complexity, material, and volume, but many providers offer lead times from a few days to a few weeks.

- Can I order prototypes and production parts from the same company? — Yes, many custom machining companies support both prototyping and full-scale production, ensuring smooth project transitions.

- What file formats are accepted for CAD models? — Most shops accept common formats such as STEP, IGES, STL, and DXF. Always confirm with your provider.

Have more questions? Contact our custom machining experts for personalized assistance and detailed technical support.

Enhance Your Competitive Edge with Custom Machining

In today’s competitive landscape, leveraging custom machining services can set your business apart by enabling faster innovation, superior product quality, and greater design flexibility. Whether you’re seeking rapid prototyping, high-precision production, or unique components for specialized industries, custom machining provides the technical capabilities and cost-effectiveness you need to succeed.

Ready to explore your options or need help sourcing the right partner? Browse our directory of top custom machining companies, read customer reviews, and request quotes to kickstart your next project.

Broaching

Broaching CNC Machining

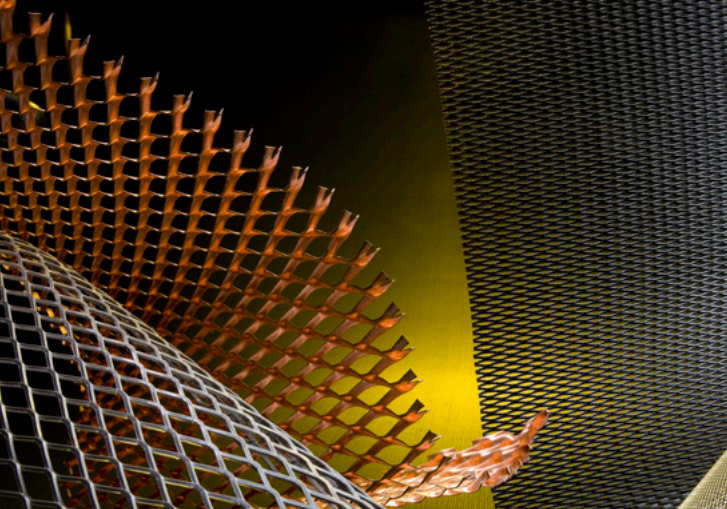

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

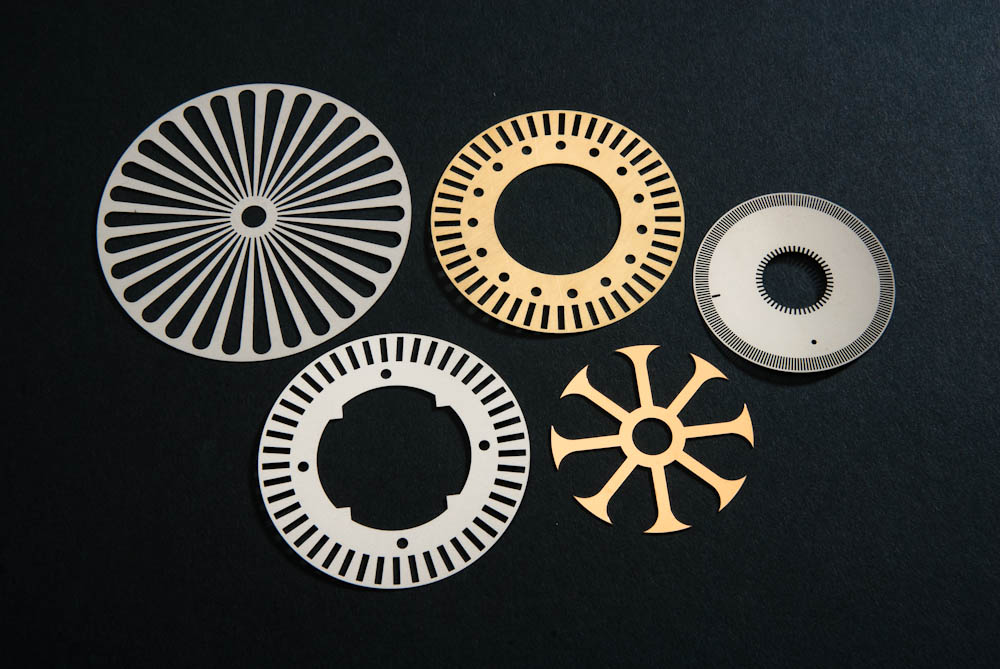

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

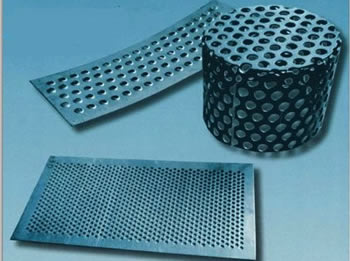

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

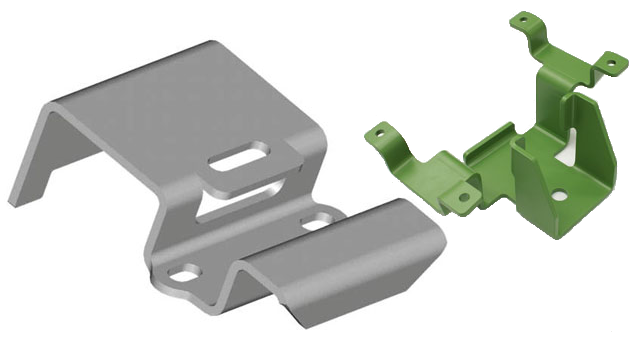

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services