Avanti Engineering, Inc.

Avanti Engineering, Inc.Request A Quote

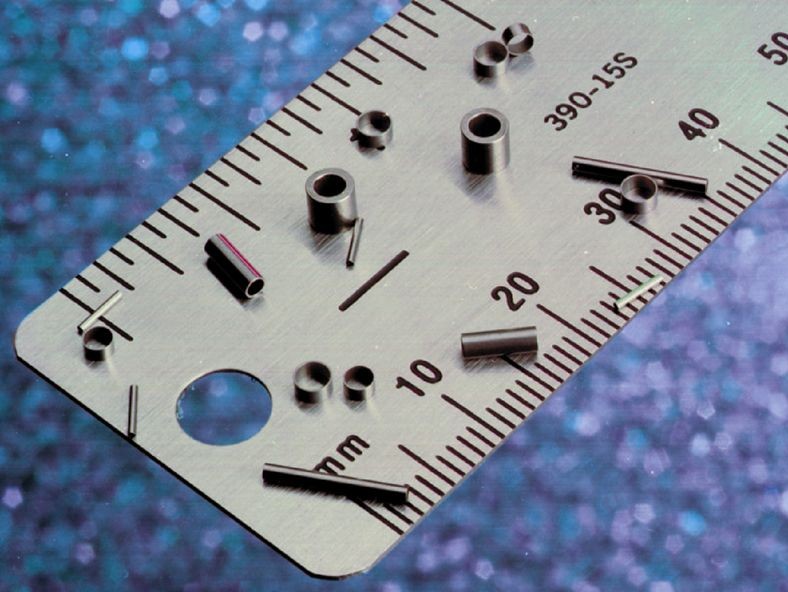

Glendale Heights, ILAt Avanti Engineering, we have been setting high standards in precision manufacturing since 1972. As a family-owned and operated business, we are proud to be ISO 9001:2015-certified, specializing in screw machine products & precision CNC-turned parts. Our advanced machinery lineup is extensive & state-of-the-art. With both single and multi-spindle screw machines, we handle standard rounds up to 2-5/8 inches, squares up to 1-9/16 inches, and hexagons up to 2-1/4 inches. Whether you require CNC turning up to 2-1/2 inches or CNC Swiss machining up to 1-1/4 inches, we are equipped to meet your needs. We also offer bar chucking up to 12 inches. In addition, we provide secondary operations, light assembly, and comprehensive inventory management to streamline your processes. Our in-house tool room allows us to design custom tools tailored specifically for your projects. Equipped with state-of-the-art toolroom equipment including CNC vertical, Wire EDM surface, contour grinders, & more. We are able to produce most cutting tools internally, saving cost & time. Our screw machine products are renowned for their precision and efficiency, making them ideal for high-volume production runs. For complex, custom parts, our CNC machining services offer the flexibility and accuracy required. We serve a wide range of industries, delivering consistent quality and reliability in every project. We take great pride in our resources, experience, and strict adherence to unmatched industry standards. Whether you need 1,000 parts or up to 20 million, we will deliver promptly, competently, and accurately. Our commitment to quality and customer satisfaction is not just a goal—it is our way of doing business. If you are ready to bring your project to life with a partner who values precision as much as you do, please contact us today. Let us work together to turn your specifications into reality.

Broaching

Broaching CNC Machining

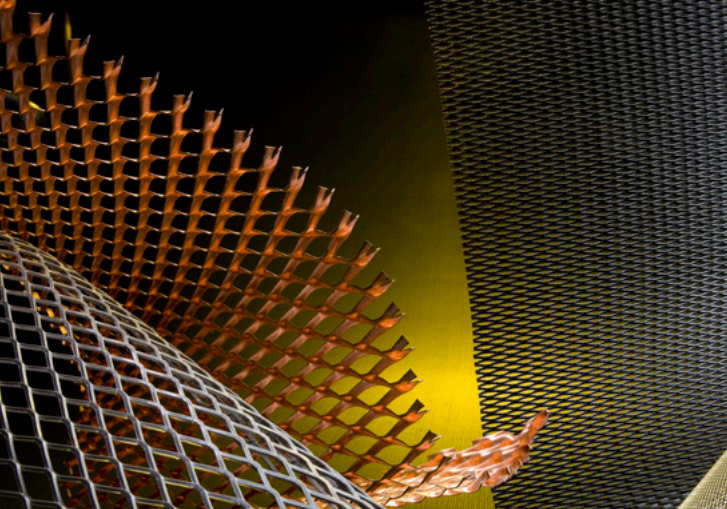

CNC Machining Expanded Metals

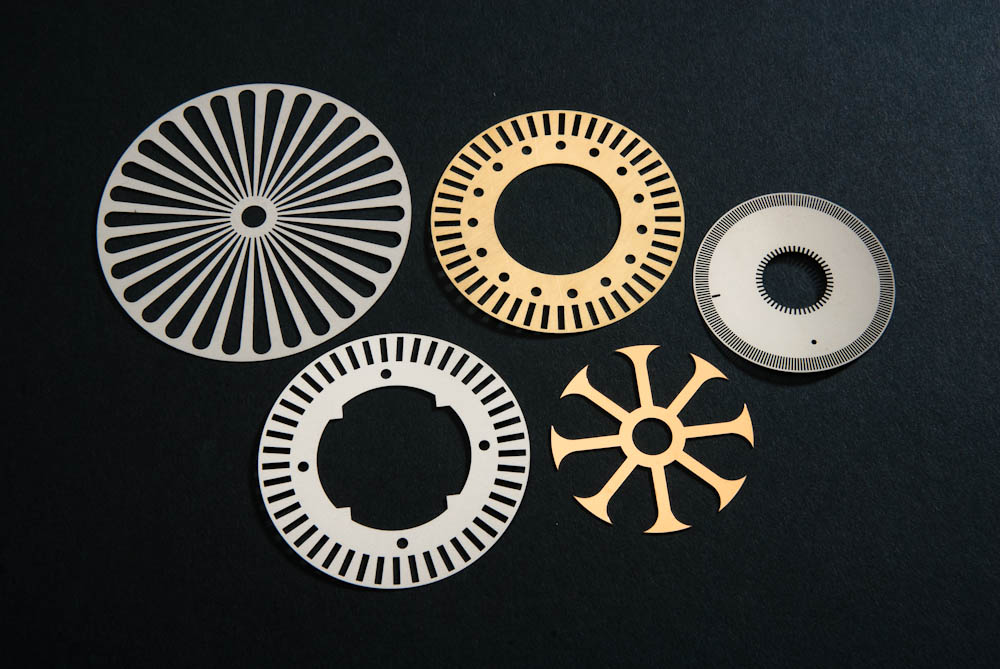

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

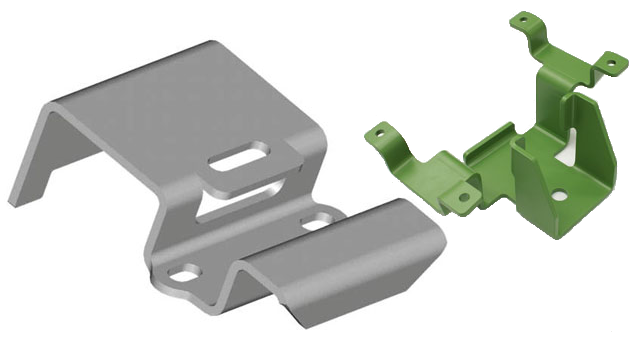

Metal Etching Metal Fabrication

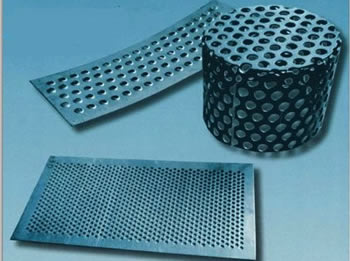

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

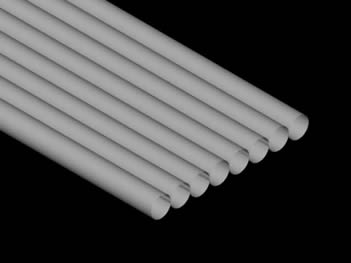

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services