Computer Numerical Control (CNC) manufacturing has revolutionized the manufacturing industry with its precision, efficiency, and reliability. It is a manufacturing process that involves the use of computer-controlled machines to produce high-quality parts and components with exceptional accuracy and consistency. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

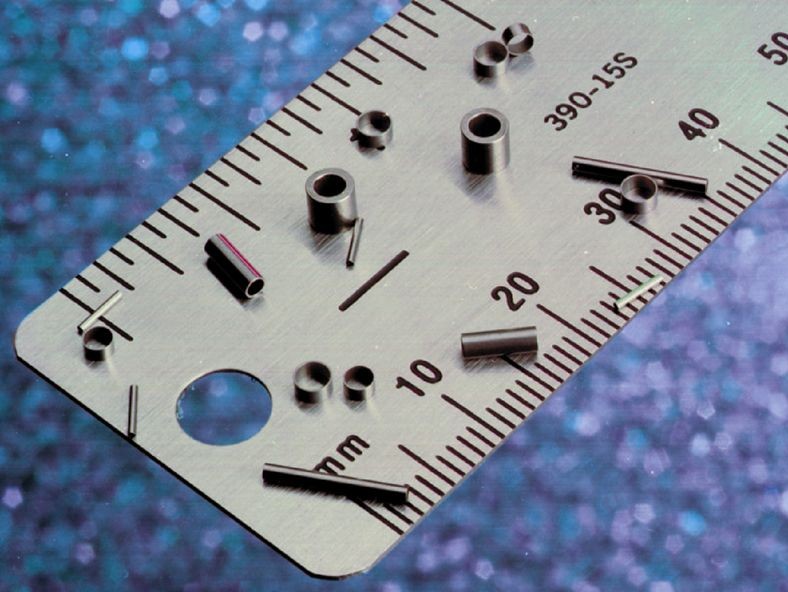

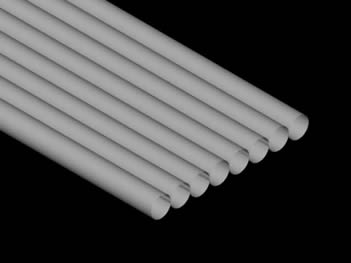

CNC Machining of high precision commercial grade parts for the electronics industry. We sell high precision Commercial Grade CNC Machine Parts. Such as Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, and 4 Axis CNC Machining. CNC Lathe and Swiss Screw Machine parts range in size from .020” to 9.0" diameter. CNC Mill parts fit within one square foot...

At JS Precision Technology, we specialize in CNC machining with a sharp focus on precision, consistency, and speed. Our team brings together deep technical knowledge and advanced equipment to produce high-tolerance components for a wide range of industries, from aerospace and automotive to electronics and medical. We thrive on complexity—transforming challenging blueprints into reality with...

At Associated MetalCast, we specialize in precision CNC machining, delivering high-quality components that meet the exacting standards of today’s industries. With decades of experience and a commitment to innovation, we bring complex designs to life with speed, accuracy, and consistency. Our state-of-the-art machining centers allow us to handle everything from short-run prototypes to full-scale ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Manufacturing Manufacturers

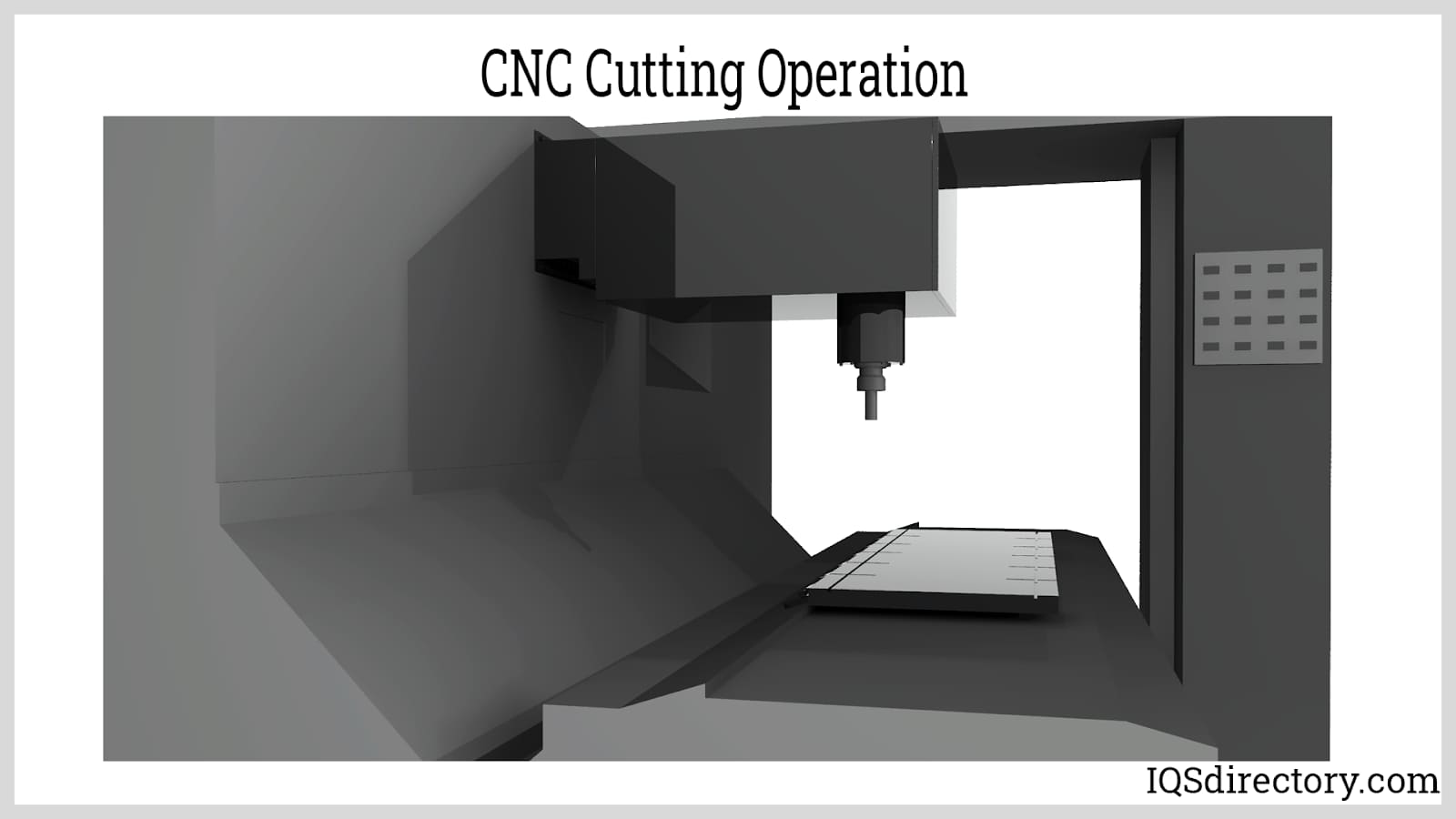

Process of CNC Manufacturing

CNC manufacturing is a multi-step process that involves the use of computer-aided design (CAD) software to create a digital model of the part or component to be manufactured. The CAD software then generates instructions in the form of a computer program that the CNC machine can read and interpret. The CNC machine then follows these instructions to cut, shape, and finish the part or component.

The process of CNC manufacturing varies depending on the specific application. For example, CNC milling involves the use of a rotating cutting tool to remove material from a block of material to create a part or component. In contrast, CNC turning uses a rotating part to shape the material into the desired shape.

Considerations Regarding CNC Manufacturing

While CNC manufacturing has several advantages, it also has several considerations which must be accounted for. One major consideration is the expensive initial setup cost of CNC machines, which may make it prohibitive for small-scale production. Additionally, technical expertise is required to program and operate the machines, which may limit accessibility for small businesses. Another consideration regarding CNC manufacturing is the limited flexibility to adjust to changes in production requirements. This is because the CNC machine follows a pre-programmed set of instructions and cannot make adjustments in real-time.

Benefits of CNC Manufacturing

Despite its limitations, CNC manufacturing offers several advantages over traditional manufacturing methods. One significant benefit is the ability to achieve high levels of accuracy and precision, which reduces the likelihood of errors and ensures consistency in production. CNC machines can also produce complex shapes and designs that would be difficult to achieve with traditional manufacturing methods. Additionally, CNC manufacturing can increase productivity and efficiency by reducing manual labor and minimizing waste. The machines can operate continuously, reducing production time and increasing output.

Applications of CNC Manufacturing

As a result of these benefits, CNC manufacturing has numerous applications in various industries, including:

Aerospace and Aviation Industries

The aerospace and aviation industries have some of the highest standards when it comes to precision and quality control. CNC manufacturing provides the ability to create complex parts with tight tolerances and high accuracy, making it a vital tool in the production of components for aircraft engines, landing gear, and other critical parts. Additionally, CNC machining can produce lightweight parts, which can improve fuel efficiency and reduce overall weight.

Automotive Industry

CNC manufacturing is used extensively in the production of automotive parts and components, including engine parts, transmission components, and suspension systems. CNC machines can produce complex parts with high accuracy and consistency, which is essential in the automotive industry. Additionally, CNC manufacturing can produce prototypes and small batches of parts quickly, which is critical in the fast-paced automotive industry.

Medical Industry

CNC manufacturing is a vital tool in the production of medical devices and equipment. It allows for the creation of complex and precise parts, including implants, surgical instruments, and other medical devices. CNC manufacturing also enables the creation of customized parts, which is crucial in the medical industry, where personalized treatments are becoming increasingly common.

Industrial Manufacturing

CNC manufacturing is used in a wide range of industrial manufacturing applications, including production machinery, tooling, and automation equipment. CNC machines can produce high-quality parts and components quickly and accurately, which is essential in industrial manufacturing.

Consumer Goods

CNC manufacturing is used in the production of consumer goods such as electronics, appliances, and home furnishings. CNC machines can produce intricate and complex parts with high accuracy, making it a valuable tool in the production of these products.

Jewelry

CNC manufacturing is used in the jewelry industry to produce intricate and precise designs. CNC machines can produce complex shapes and patterns, allowing jewelry designers to create unique and intricate pieces that would be difficult or impossible to create by hand.

Defense Industry

CNC manufacturing is used in the production of military equipment and weaponry. CNC machines can produce high-precision parts and components that meet strict military specifications.

Architecture and Construction

CNC manufacturing is used in the production of architectural components such as staircases, handrails, and decorative elements. CNC machines can produce complex and detailed designs quickly and accurately, making it a valuable tool for architects and designers.

In-House vs. Outsourced CNC Manufacturing

The decision to perform CNC manufacturing in-house or outsource it to a service provider depends on several factors. In-house CNC manufacturing provides more control over the production process and allows for greater flexibility in making changes to the design or production schedule. However, it requires significant capital investment in CNC machines and technical expertise.

By outsourcing to a service provider, on the other hand, businesses can leverage the provider's investment in skilled and knowledgeable staff, the latest equipment, software, and technologies, and advanced production capabilities. It also allows for greater flexibility in responding to changes in demand. Lastly, outsourcing CNC manufacturing allows businesses to save on labor and equipment costs and reduce overhead expenses such as rent, utilities, and maintenance.

Choosing the Proper CNC Manufacturing Service

To ensure you have the most positive outcome when choosing a CNC manufacturing service, it is important to compare several companies using our directory of CNC manufacturing services. Each CNC manufacturing service has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or to request a quote. Review each CNC manufacturing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple CNC manufacturing services with the same form.

Broaching

Broaching CNC Machining

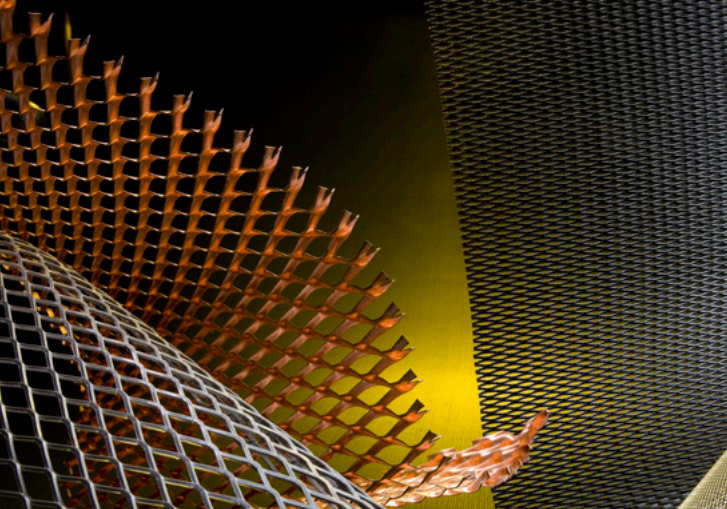

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

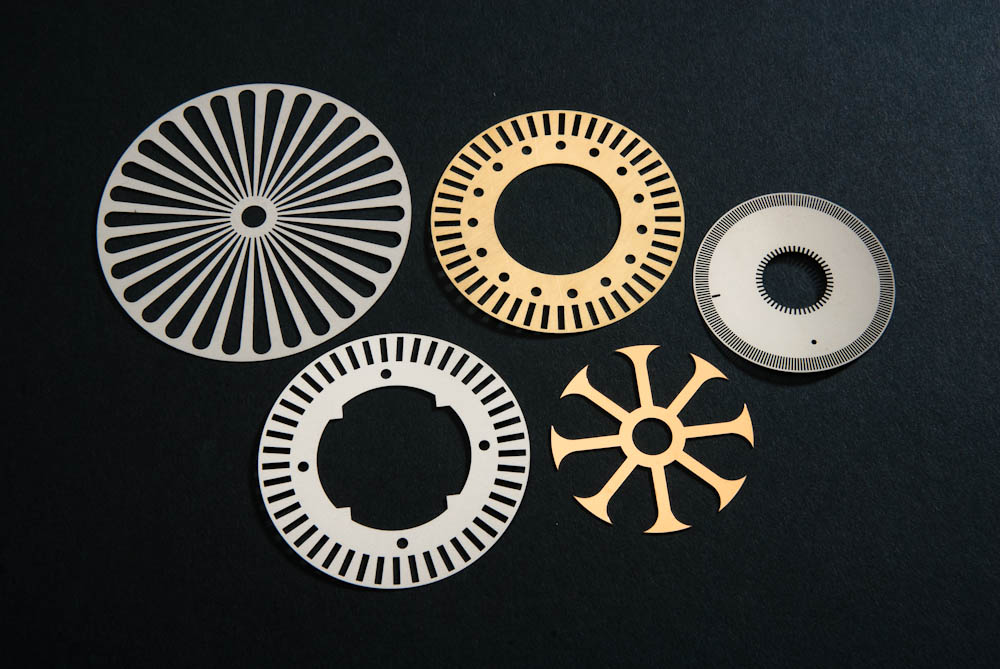

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

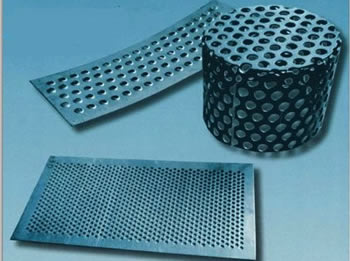

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

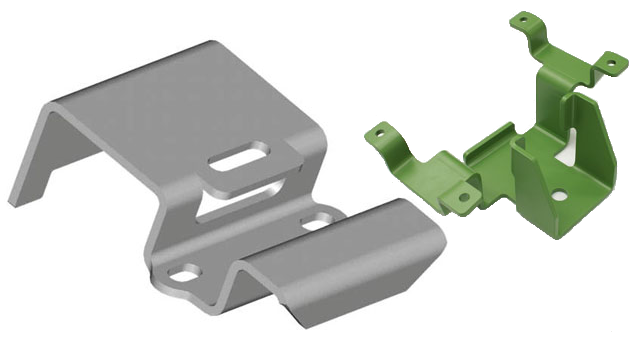

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services