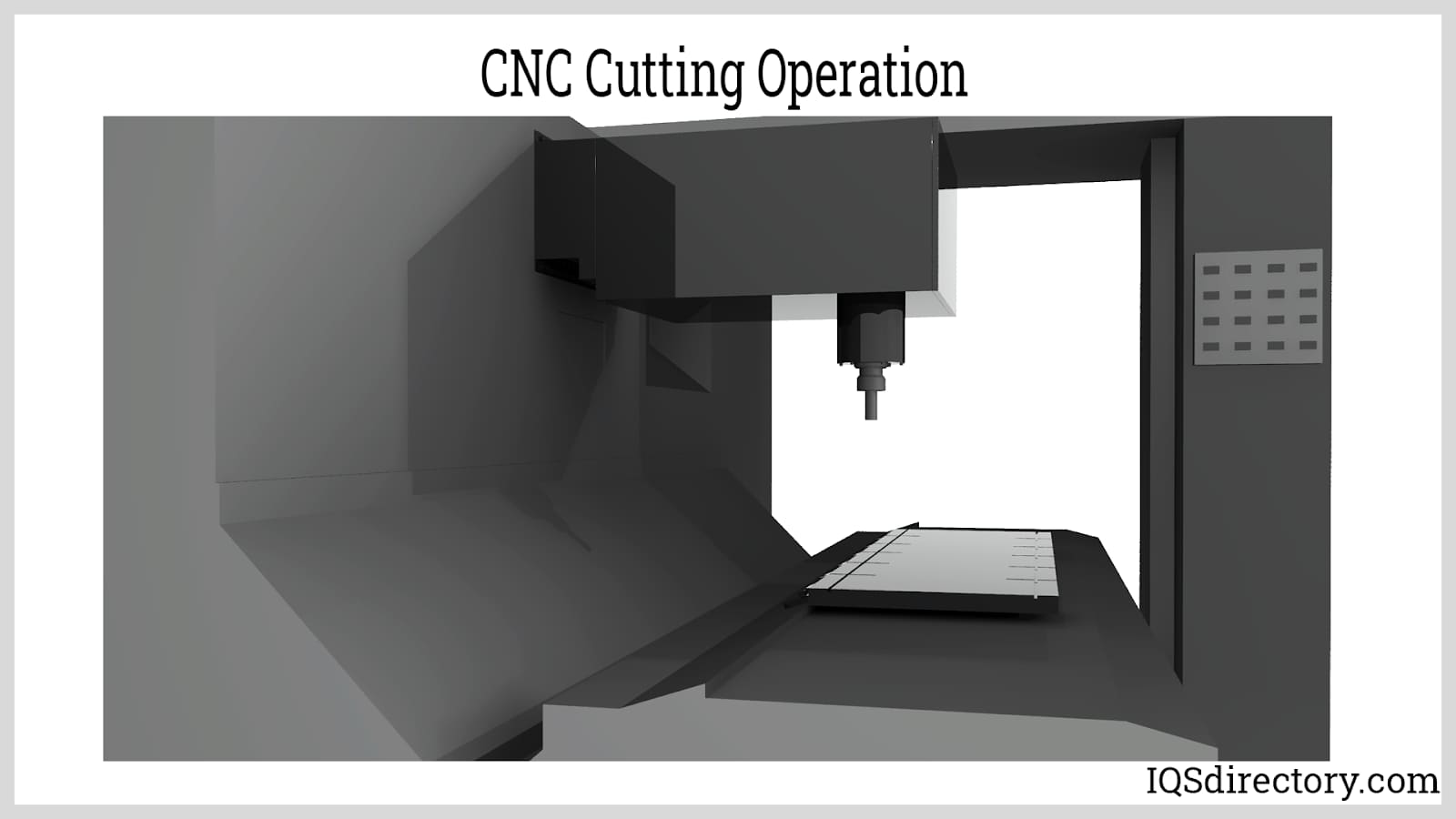

Computer Numerical Control (CNC) machines have become an integral part of modern manufacturing processes. These machines use computer programs to control the movement of cutting and shaping tools to produce high-precision and accurate parts. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

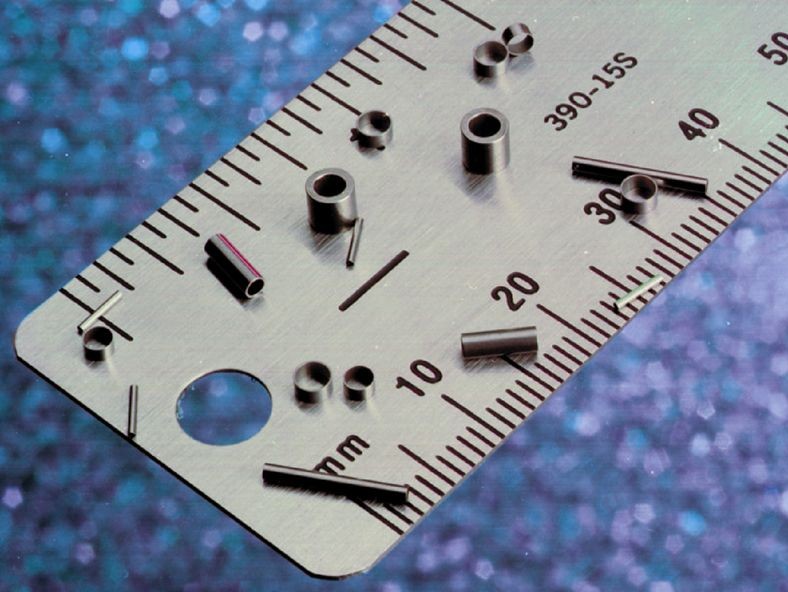

CNC Machining of high precision commercial grade parts for the electronics industry. We sell high precision Commercial Grade CNC Machine Parts. Such as Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, and 4 Axis CNC Machining. CNC Lathe and Swiss Screw Machine parts range in size from .020” to 9.0" diameter. CNC Mill parts fit within one square foot...

At JS Precision Technology, we specialize in CNC machining with a sharp focus on precision, consistency, and speed. Our team brings together deep technical knowledge and advanced equipment to produce high-tolerance components for a wide range of industries, from aerospace and automotive to electronics and medical. We thrive on complexity—transforming challenging blueprints into reality with...

At Associated MetalCast, we specialize in precision CNC machining, delivering high-quality components that meet the exacting standards of today’s industries. With decades of experience and a commitment to innovation, we bring complex designs to life with speed, accuracy, and consistency. Our state-of-the-art machining centers allow us to handle everything from short-run prototypes to full-scale ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More CNC Service Manufacturers

Limitations of Owning CNC Equipment

While Computer Numerical Control (CNC) machines have revolutionized modern manufacturing, there are notable limitations that make owning CNC equipment challenging for many businesses. First and foremost, the initial investment in CNC machinery can be significant—industrial-grade CNC mills, lathes, routers, and other equipment often cost tens or even hundreds of thousands of dollars. This capital outlay includes not only the machines themselves but also the costs of software, tooling, setup, and facility adjustments. For startups and small-to-medium manufacturers, these upfront CNC machine costs can be prohibitive.

Additionally, CNC machines require specialized training to operate safely and efficiently. Operators must understand complex programming languages such as G-code, as well as the nuances of toolpath optimization and machine maintenance. Hiring or training skilled CNC machinists adds to the overall cost of ownership and ongoing labor expenses. Furthermore, maintenance for CNC machines is critical; these sophisticated systems need regular calibration, part replacement, and troubleshooting to prevent costly breakdowns and downtime. Spare parts and service contracts can be expensive, and unexpected repairs can disrupt production schedules.

Another consideration is the rapid pace of technological advancement in CNC machinery. Owning CNC equipment may result in obsolescence as new models with improved capabilities, automation features, and software integrations become available. Upgrading or retrofitting existing CNC machines to keep up with industry trends involves additional investment and operational disruption. For businesses with fluctuating production needs, the fixed costs and inflexibility of in-house CNC ownership can reduce competitiveness and adaptability in a dynamic manufacturing landscape.

Are you considering whether to invest in your own CNC equipment or outsource machining needs? Explore our detailed comparison below to help you make the right decision for your manufacturing operations.

What Are CNC Services?

CNC services refer to third-party providers that offer access to advanced CNC machining capabilities without the need for businesses to purchase or maintain their own equipment. These precision machining services utilize high-tech CNC machines, including CNC milling, CNC turning, multi-axis machining, and laser cutting, to fabricate custom parts and components based on client specifications. By leveraging a CNC service provider, manufacturers, engineers, designers, and entrepreneurs can obtain custom CNC parts with exceptional accuracy and repeatability, supporting a wide range of applications across industries.

CNC service companies typically offer a comprehensive suite of solutions, including CAD/CAM design support, rapid prototyping, small- to large-batch production, finishing, assembly, and quality assurance. They work with a diverse selection of materials, such as aluminum, stainless steel, titanium, plastics, composites, and exotic alloys, catering to unique project requirements. Many CNC service firms provide flexible order quantities, from one-off prototypes to high-volume production runs, enabling businesses to scale efficiently according to demand.

Looking for a reliable CNC machining partner for your next project? Discover how CNC services can streamline your product development, reduce costs, and accelerate time-to-market with expert manufacturing solutions.

Considerations Regarding CNC Services

While CNC services offer numerous advantages, there are important factors to weigh before selecting a CNC machining provider. One of the primary considerations is the level of control over the manufacturing process. When outsourcing to a third-party CNC shop, businesses may have less visibility into day-to-day operations, quality assurance protocols, and workflow prioritization. This reduced oversight can result in potential production delays, especially if a service provider is managing multiple client projects or experiences unforeseen technical issues.

Another aspect to assess is the degree of customization available through CNC services. Some providers may have limitations in terms of machine size, axis configuration, or material compatibility, affecting the ability to fabricate highly specialized or unconventional parts. Businesses with strict intellectual property concerns should also consider the safety and confidentiality of their design files when partnering with an external CNC machining service.

Additionally, communication and logistics play a critical role in successful outsourcing. Differences in lead times, shipping costs, quality standards, and after-sales support can impact overall satisfaction with CNC service providers. It is essential to evaluate providers based on experience, certifications (such as ISO 9001, AS9100, or ITAR compliance), and track record in similar industries.

Curious about how to choose the best CNC service provider for your needs? Scroll down for our actionable checklist and key factors to consider when evaluating CNC machining companies.

Benefits of CNC Services

Embracing CNC services unlocks a host of benefits for businesses seeking quality manufacturing solutions without the burden of equipment ownership. Here are some of the most compelling reasons to consider partnering with a CNC machining service:

- Cost-Effectiveness: By outsourcing CNC machining, companies avoid hefty capital expenditures on equipment, maintenance, and skilled labor. This enables better cash flow and frees up resources for core business activities.

- Access to Advanced Technology: CNC service providers invest in state-of-the-art machinery, multi-axis machining centers, and software, ensuring access to the latest manufacturing innovations and capabilities.

- Precision and Consistency: CNC machining services deliver extremely tight tolerances, repeatability, and intricate geometries, meeting even the most demanding engineering requirements.

- Faster Lead Times: Professional CNC shops can rapidly prototype and produce parts, helping clients accelerate product development cycles and reduce time-to-market.

- Scalability: CNC services support flexible production volumes, from prototypes and short runs to mass production, allowing businesses to scale efficiently as demand fluctuates.

- Material Versatility: CNC machining services offer a wide range of material options, including metals, plastics, composites, and specialty alloys for diverse applications.

- Quality Assurance: Reputable CNC service providers employ rigorous inspection, measurement, and testing protocols to ensure parts meet exact specifications and industry standards.

- Design Support and Engineering Expertise: Many CNC service companies have in-house engineers who work collaboratively to optimize designs for manufacturability, cost, and performance.

- Reduced Risk and Liability: Outsourcing production to certified CNC service providers helps companies mitigate the risks associated with equipment failure, compliance, and workforce management.

Want to learn more about how CNC machining services can help your business save money, boost productivity, and innovate faster? Contact our recommended CNC service providers or request a free quote today.

Applications of CNC Services

Thanks to their precision, versatility, and scalability, CNC services are integral to a broad spectrum of industries and product categories. Below are key sectors that leverage CNC machining services for prototyping, production, customization, and innovation. Explore these use cases and discover why CNC services are a strategic choice for manufacturers worldwide.

Automotive Industry

The automotive sector relies heavily on CNC machining services for the fabrication of high-performance components and assemblies. Applications include engine blocks, transmission housings, cylinder heads, suspension parts, brake calipers, wheels, and custom body panels. CNC machining ensures optimal fit, durability, and repeatability—key requirements for both mass production and motorsport prototyping.

Case study: A leading automotive parts supplier needed to produce thousands of precision engine blocks with strict dimensional tolerances and surface finishes. By partnering with a CNC service provider offering bulk discounts and advanced quality control, the company achieved faster turnaround and significant cost savings compared to in-house production.

Are you searching for a reliable CNC machining solution for automotive parts? Explore our directory of vetted automotive CNC service providers to find the right partner for your project.

Aerospace Industry

The aerospace industry demands uncompromising accuracy, material traceability, and regulatory compliance. CNC machining services are essential for manufacturing complex components such as turbine blades, landing gear assemblies, airframe brackets, and custom wing structures from high-strength materials like titanium and Inconel.

Case study: An aerospace engineering firm required a custom wing rib for a prototype aircraft. Utilizing a CNC service with AS9100 certification enabled the firm to achieve micron-level tolerances, meet stringent safety standards, and rapidly iterate designs before flight testing.

Need aerospace-grade CNC machining? Connect with our network of certified aerospace CNC service providers.

Medical Industry

Precision and cleanliness are paramount in medical manufacturing. CNC services are widely used for producing surgical instruments, orthopedic implants, dental devices, prosthetics, and diagnostic equipment. Machining biocompatible materials like titanium, stainless steel, and PEEK ensures patient safety and device performance.

Case study: A medical device startup needed a custom neurosurgical tool with intricate features and tight tolerances. By leveraging a CNC machining service specializing in medical components, the company was able to validate its design and scale up production for clinical trials without investing in new equipment.

Have a medical device project? Discover CNC service providers with specialized experience in healthcare manufacturing.

Construction Industry

In construction, CNC machining services are used to produce architectural components such as window frames, door casings, curtain wall elements, and decorative panels. CNC routers and mills enable fabrication of complex shapes and custom dimensions in wood, metal, and composite materials, supporting both residential and commercial projects.

Case study: A commercial builder commissioned a CNC service to manufacture bespoke window frames and aluminum façade panels for a landmark office tower. This approach ensured exact dimensional matching and reduced on-site installation time.

Looking to streamline your construction supply chain? Find CNC machining partners specializing in building products and architectural elements.

Jewelry Industry

The jewelry sector uses CNC services to produce intricate, custom-designed rings, necklaces, bracelets, and watch components. CNC milling and engraving allow for the precise execution of unique patterns, filigree, and gemstone settings in precious metals and modern materials like titanium and ceramics.

Case study: A boutique jewelry brand collaborated with a CNC service to realize a collection of complex engagement rings with customized settings. The partnership enabled rapid prototyping, consistent quality, and the flexibility to fulfill bespoke orders for discerning clients.

Curious about custom jewelry manufacturing? Browse our featured jewelry CNC machining services for creative design and production support.

Prototyping

Rapid prototyping is a cornerstone of product innovation, and CNC services play a pivotal role by delivering functional prototypes in days rather than weeks. CNC machining produces prototypes from actual engineering materials, allowing for realistic testing and validation before committing to high-volume manufacturing.

Case study: An industrial design agency utilized a CNC service to create working prototypes of a consumer electronics device. This enabled iterative design improvements, hands-on evaluation, and a faster path to mass production readiness.

Need a prototype fast? Connect with our rapid prototyping CNC service experts for quick-turn solutions.

Electronics Industry

CNC machining services are critical for fabricating custom enclosures, heat sinks, circuit boards, and connectors for electronics. High-precision machining ensures proper fit and function in compact devices, wearables, and high-frequency applications.

Case study: An electronics manufacturer required a low-volume production run of custom aluminum housings for a new IoT device. CNC machining delivered the necessary accuracy, surface finish, and EMI shielding, allowing the product to launch on schedule.

Searching for electronics CNC machining? Review our list of providers specializing in electronic component fabrication.

Furniture Industry

Modern furniture designers use CNC services to produce custom chairs, tables, cabinets, and decorative elements in wood, metal, and composite materials. CNC routing and milling enable mass customization and the creation of complex curves, joinery, and patterns that are difficult to achieve by hand.

Case study: A contract furniture maker used a CNC service to meet a tight deadline for a hospitality project, producing a large batch of custom-designed chairs with flawless repetition and finish.

Interested in custom furniture manufacturing? Explore our curated CNC machining partners for the furniture industry.

Toy Industry

Toy companies rely on CNC services to create detailed models, figurines, game pieces, and educational kits. CNC machining supports rapid prototyping and short production runs, ensuring accuracy, safety, and repeatability for children’s products.

Case Study: A board game publisher worked with a CNC service to produce precision-milled game pieces from colorful plastics. The service’s ability to produce consistent, high-quality pieces enabled a successful product launch and positive reviews from customers.

Looking for a toy manufacturing partner? Connect with CNC machining services specializing in toy and game component production.

Art Industry

Artists and sculptors increasingly use CNC services to realize complex installations, abstract sculptures, and large-scale public art. CNC machining allows for the translation of digital models into physical objects with fine detail, symmetry, and repeatability.

Case Study: A contemporary sculptor utilized a CNC service to fabricate an intricate metal installation for a museum exhibit. The process enabled the artist to scale up their design and ensure perfect execution of each piece.

Want to explore art fabrication with CNC technology? Discover CNC service providers with experience in creative and artistic projects.

Sports Equipment Industry

Manufacturers of sports equipment use CNC machining services to produce golf club heads, tennis racket frames, bicycle components, and hockey sticks. CNC technology ensures precise weight distribution, balance, and aerodynamic properties, supporting both mass production and athlete-specific customization.

Case Study: A premium golf club brand collaborated with a CNC service to design and produce personalized club heads tailored to professional athletes’ performance metrics. The result was improved player satisfaction and product differentiation in a competitive market.

Interested in custom sports equipment manufacturing? Contact CNC service providers specializing in sports gear fabrication.

How to Choose the Right CNC Service Company

With the growing number of CNC machining services available, selecting the right partner can be a critical decision for your project’s success. Here are essential steps and criteria to guide your evaluation process:

- Assess Capabilities: Review each CNC service company's range of equipment, supported materials, and machining processes (such as 3-, 4-, and 5-axis machining, EDM, or Swiss turning). Do they offer secondary services like finishing, assembly, or inspection?

- Check Industry Experience: Does the provider have a proven track record in your specific industry—be it aerospace, medical, automotive, or consumer products?

- Verify Certifications: Look for credentials such as ISO 9001, AS9100, or ITAR compliance, which demonstrate commitment to quality and regulatory standards.

- Evaluate Precision and Quality Control: Inquire about their quality assurance processes, inspection equipment, and tolerance capabilities. Request sample parts or case studies if available.

- Review Lead Times and Flexibility: Consider order turnaround times, minimum/maximum batch sizes, and the provider’s ability to accommodate urgent or custom projects.

- Compare Pricing and Value: Request detailed quotes and compare total costs, including tooling, setup, material, and shipping. Factor in the value of design support and customer service.

- Read Client Reviews: Check testimonials, online reviews, and references for insights into reliability, communication, and after-sales support.

- Test Communication: A responsive and knowledgeable team is crucial for clear project updates and issue resolution. Test their responsiveness with pre-sales inquiries.

Our comprehensive directory of CNC service companies makes your search effortless. Each provider features a business profile highlighting their specialties, capabilities, and certifications. Use our integrated contact forms to request more information or obtain a customized quote. Preview each CNC service company’s website instantly and leverage our streamlined RFQ form to contact multiple providers with a single inquiry.

Still have questions about choosing a CNC machining partner? Contact us today to speak with an expert advisor or explore our Frequently Asked Questions section for more insights on CNC services, applications, and best practices.

Frequently Asked Questions About CNC Services

What is CNC machining and how does it work?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled machines remove material from a solid block (workpiece) to create custom parts and components. The process is driven by digital CAD/CAM files, ensuring high accuracy, repeatability, and the ability to produce complex geometries.

What materials can be machined using CNC services?

CNC services can machine a vast range of materials, including metals (aluminum, steel, titanium, brass, copper), plastics (ABS, polycarbonate, nylon, PEEK), composites, wood, and specialty alloys. The choice of material depends on the application, mechanical properties, and budget.

How do I get a quote for CNC machining services?

To receive a quote, upload your part design (in STEP, IGES, or STL format) using the provider’s online portal or contact form. Specify material, quantity, tolerances, finishing requirements, and desired lead time. Most CNC service companies respond within 24 to 48 hours with a detailed estimate.

What are typical lead times for CNC machined parts?

Lead times vary based on complexity, order size, and provider capacity, but rapid prototyping jobs can often be completed in 1-5 business days. Production orders may take 1-3 weeks. Always confirm lead times upfront for planning purposes.

Is CNC machining suitable for both prototypes and mass production?

Yes. CNC services are highly flexible, making them ideal for rapid prototyping, bridge production, and full-scale manufacturing. The process supports both one-off parts and large-volume runs with consistent quality.

What quality standards do reputable CNC service providers follow?

Top CNC machining companies adhere to strict quality management systems, such as ISO 9001, AS9100 (aerospace), ISO 13485 (medical), and ITAR (defense). Look for these certifications when choosing a CNC partner to ensure compliance and reliability.

Can CNC services assist with design and engineering?

Many CNC service companies offer value-added engineering support, including design for manufacturability (DFM) analysis, material selection advice, and CAD/CAM optimization to help clients achieve the best results at optimal cost.

Have a specific question not covered here? Contact our team for expert CNC guidance or to discuss your unique project requirements.

Broaching

Broaching CNC Machining

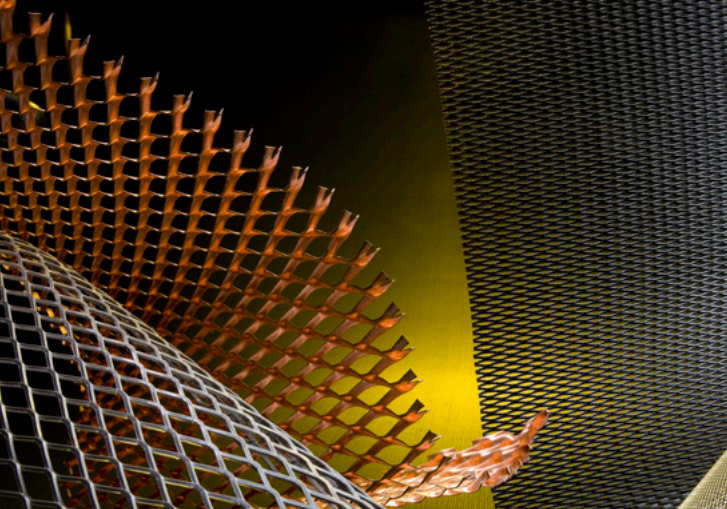

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

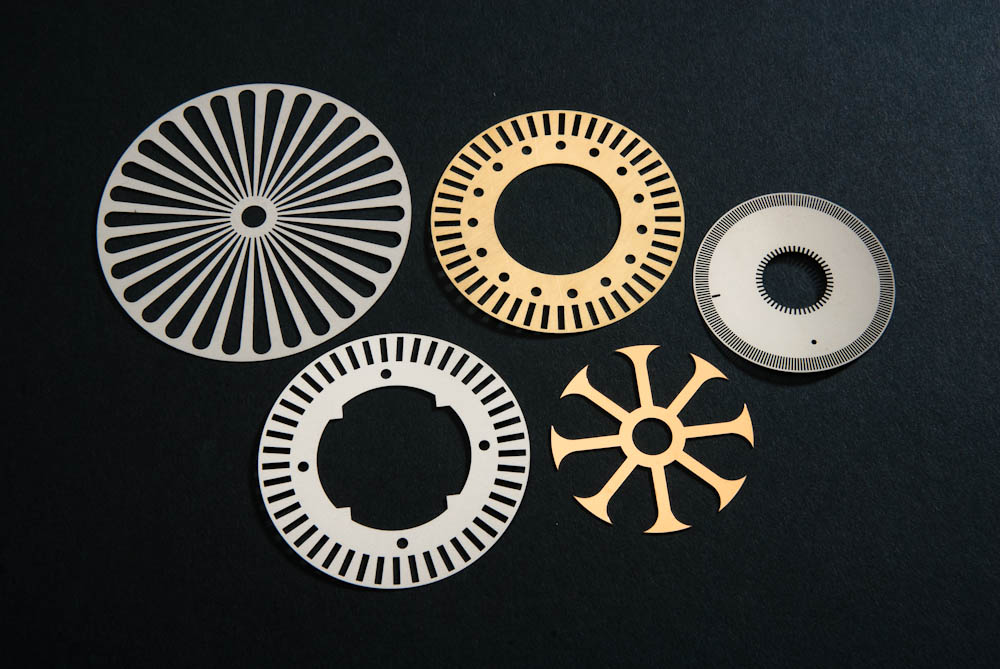

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

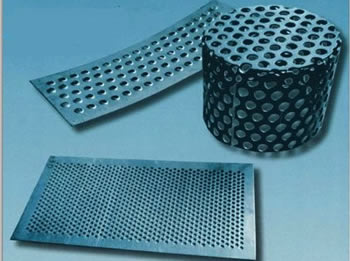

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

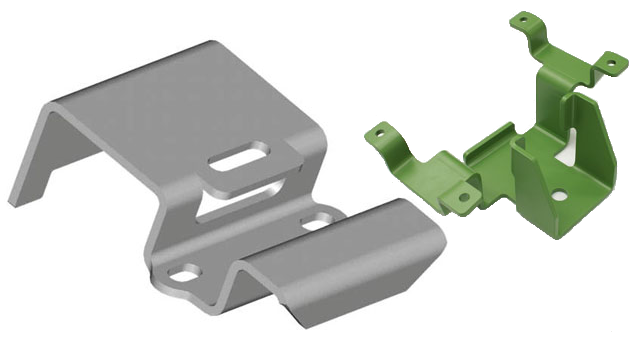

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services