Micro Metals Inc.

Micro Metals Inc.Request A Quote

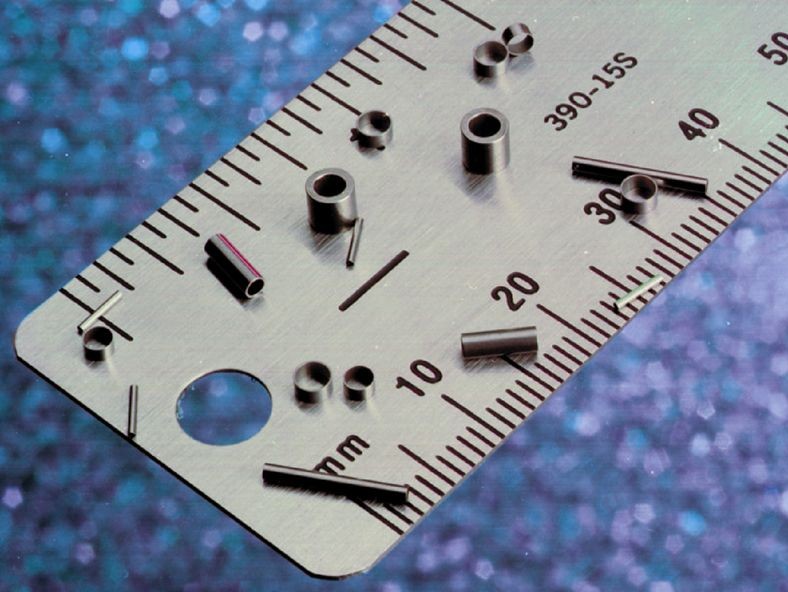

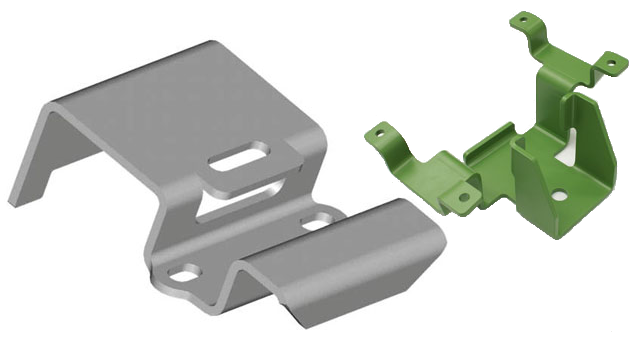

Colorado Springs, COAt Micro Metals Inc., we take pride in our commitment to precision and quality in every aspect of our CNC machining operations. Our team of skilled professionals utilizes state-of-the-art CNC technology to deliver custom metal components that meet the most demanding specifications. We understand the importance of accuracy and consistency in manufacturing, which is why we continuously invest in advanced machinery and training to ensure that our processes align with industry standards and client expectations. We specialize in producing complex and high-precision parts, accommodating a wide range of materials and tolerances. Our expertise spans from prototyping to full-scale production, and we are equipped to handle both small and large-volume orders with the same dedication to excellence. Our engineers work closely with clients to understand their unique requirements, allowing us to develop tailored solutions that enhance performance and functionality. Through rigorous quality control measures and comprehensive testing, we ensure that every product leaving our facility meets our strict standards. We place a strong emphasis on continuous improvement, regularly assessing our techniques and procedures to optimize efficiency and precision. By fostering a culture of innovation and quality, we have built lasting relationships with clients across various industries who rely on our expertise to support their manufacturing needs. At Micro Metals Inc., we believe that our success is directly tied to the satisfaction of our clients. We strive to exceed expectations by delivering superior products on time and within budget. Our commitment to craftsmanship and customer service remains at the core of everything we do, allowing us to maintain our reputation as a trusted partner in CNC machining.

Leading CNC Machining Companies

More CNC Machining Companies

Additional Categories: AGV

Broaching

Broaching CNC Machining

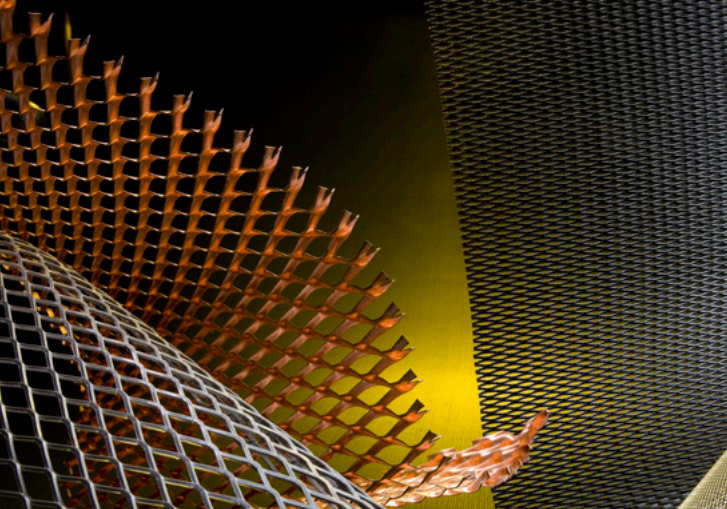

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

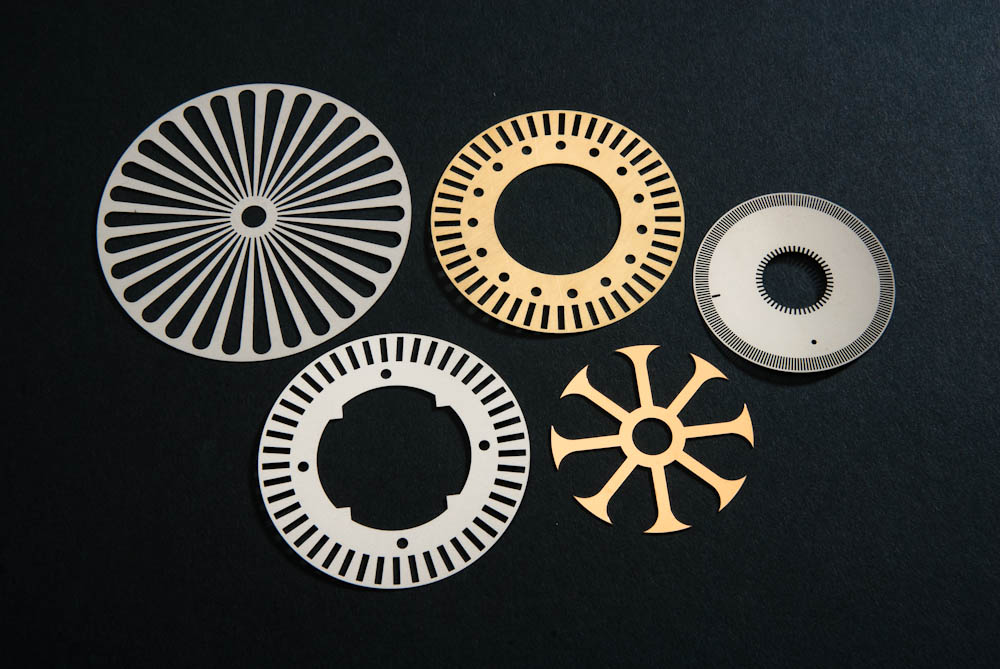

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

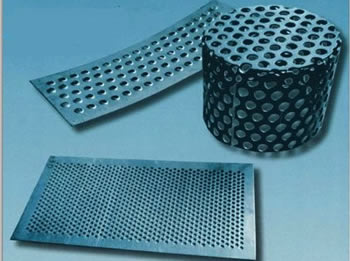

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services