Precision machining is a type of technical manufacturing essential for creating and designing parts, tools, machines, and other hardware. These precision-machined products are essential in modern manufacturing for maintaining process controls and tolerances that work under extremely tight specifications. Read More…

At GrovTec Machining, we pride ourselves on being the go-to destination for precision turned components and screw machine products. When it comes to fulfilling your machining needs, you need not look any further than our state-of-the-art screw machine shop. Our dedicated team of experienced machinists and cutting-edge equipment allow us to tackle projects of all sizes and complexities.

Our advanced CNC machining centers are equipped with the latest technology, enabling us to produce intricate and accurate parts with tight tolerances. Our team of skilled programmers and machinists can efficiently handle both small and large production runs, delivering exceptional results every time. Whether it's prototyping or full-scale production, we are committed to meeting your CNC machining ...

CNC Machining of high precision commercial grade parts for the electronics industry. We sell high precision Commercial Grade CNC Machine Parts. Such as Swiss Screw Machining, 5 Axis CNC Lathe Machining, Vertical Milling, Horizontal Milling, and 4 Axis CNC Machining. CNC Lathe and Swiss Screw Machine parts range in size from .020” to 9.0" diameter. CNC Mill parts fit within one square foot...

At JS Precision Technology, we specialize in CNC machining with a sharp focus on precision, consistency, and speed. Our team brings together deep technical knowledge and advanced equipment to produce high-tolerance components for a wide range of industries, from aerospace and automotive to electronics and medical. We thrive on complexity—transforming challenging blueprints into reality with...

At Associated MetalCast, we specialize in precision CNC machining, delivering high-quality components that meet the exacting standards of today’s industries. With decades of experience and a commitment to innovation, we bring complex designs to life with speed, accuracy, and consistency. Our state-of-the-art machining centers allow us to handle everything from short-run prototypes to full-scale ...

With nearly 40 years industry experience, we have what it takes to satisfy your every need. We are committed to our CNC machining quality, as our ISO 9001:2008 certification shows.

Thuro Metal Products is a CNC machining service provider. Our expertise is in the utilization of CNC controlled turning and milling machines as well as multi-spindle, single spindle, and Swiss screw machines.

More Precision Machining Manufacturers

Precision machining is a cornerstone of modern manufacturing, utilized in producing countless large and small objects and their components used in everyday life. From aerospace components and automotive parts to medical devices and consumer electronics, the demand for high-precision engineering continues to grow as industries seek tighter tolerances, improved product performance, and reliable repeatability.

Whenever an object consists of many small, interacting parts, it's usually manufactured using precision machining processes to ensure these parts fit together seamlessly and function with optimal performance. This advanced manufacturing discipline involves harnessing the highest capabilities of specialized tools, state-of-the-art engineering equipment, and sophisticated software programs. These machines and technologies not only expand the boundaries of design feature creation and material utilization but also deliver operations under exceptionally tight tolerances, defined by industry-specific and sometimes highly customized manufacturing parameters.

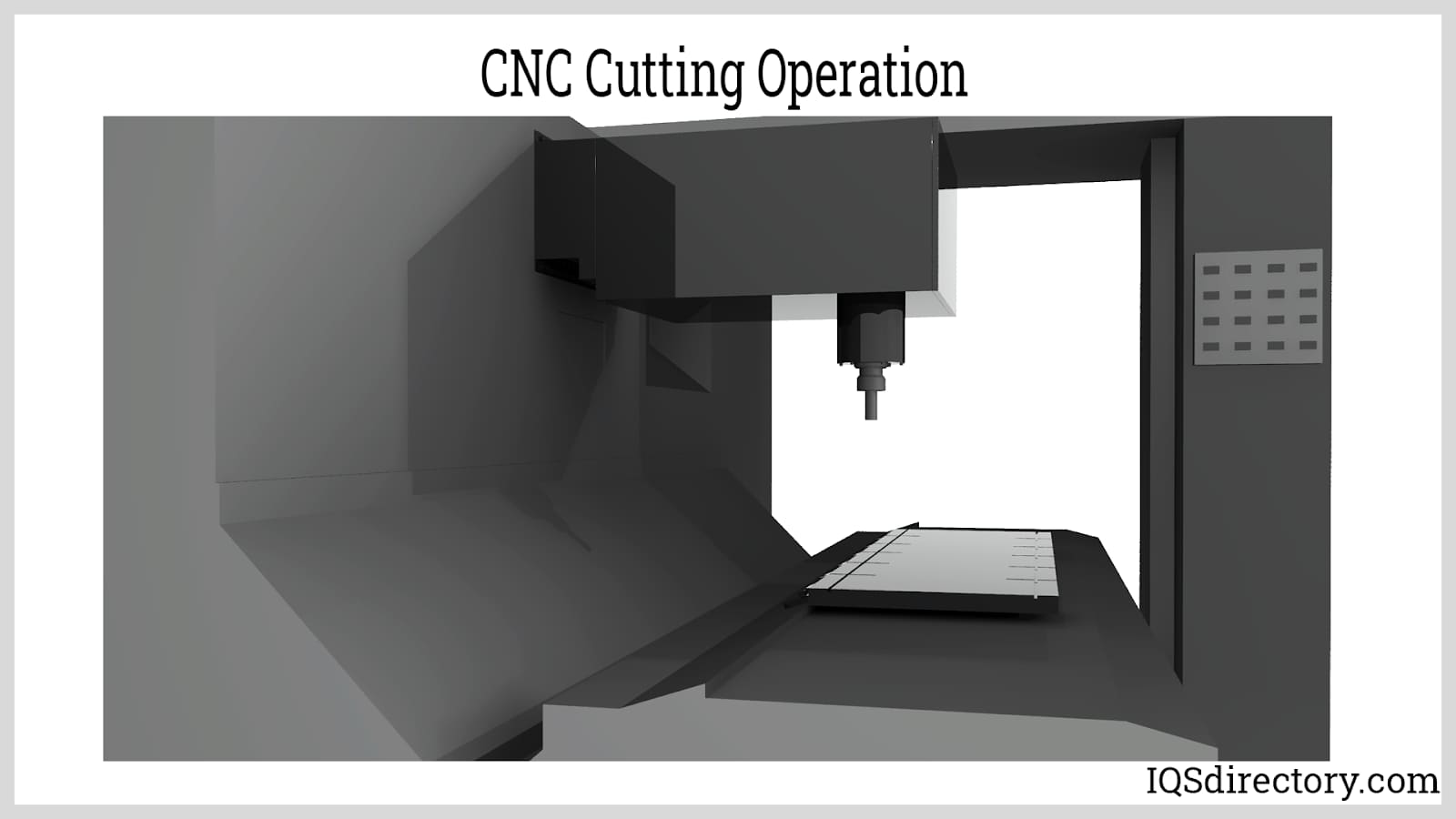

In essence, precision machining services involve the careful removal of excess raw material from a workpiece, all while maintaining a near-perfect tolerance finish. Put simply, this process transforms larger material stock into smaller, highly accurate components that strictly adhere to engineering specifications and stringent quality standards. This subtractive manufacturing method frequently employs computer numerical control (CNC) machines, which offer unmatched accuracy and repeatability in milling, cutting, turning, and electrical discharge machining (EDM).

Across industries, both common and highly specialized products are brought to life through precision machining. Whether it’s the restoration of worn-out equipment—requiring welding, grooving, or machine tool calibration—or the manufacturing of intricate assemblies, a baseline of machining skill is essential for every component. From the automotive sector to the production of medical instruments and aircraft components, precision machining underpins technological advancement and product reliability. In short, if your product contains multiple parts, precision machining is almost certainly involved in its creation.

The Working Principles of Precision Machining

Precision machining operates on a subtractive manufacturing principle. Raw materials—such as metals, ceramics, plastics, or composites—are shaped and refined using engineered tools, proprietary software, and multi-step processes to create finely featured, complex products. The process is typically guided by computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which allow manufacturers to meet specific design requirements, maintain tight tolerances, and optimize productivity.

Success in precision machining depends on the machinist’s ability to interpret and execute highly detailed digital blueprints—often created in advanced 3D modeling software. These CAD/CAM files are translated into machine-readable code for CNC operations, dictating every movement and parameter of the manufacturing process. For optimal results, high-resolution plans are developed with meticulous attention to detail, ensuring that the finished parts meet or exceed client expectations and regulatory standards.

While most modern precision machining companies leverage automated CAD/CAM workflows, the initial conceptualization phase may still involve hand-drawn sketches or custom designs, especially for prototyping or specialized projects. Precision machinists are required to work with a diverse range of materials—such as stainless steel, aluminum, titanium, glass, graphite, polymers, and engineered alloys. As a result, the choice of material and project scale influences the selection of machining techniques and equipment.

To deliver the required forms and finishes, machinists utilize an array of tools and technologies, including drill presses, surface grinders, vertical and horizontal milling machines, CNC lathes, band saws, and even robotics for automated production lines. Mastery in CNC programming and real-time process monitoring is essential for modern machinists, as is a deep understanding of material properties and toolpath optimization.

Are you researching the fundamentals of CNC machining or looking to understand how precision machining can benefit your product? Explore common use cases and industry applications below.

Types of Precision Machining

Modern precision machining is powered by a diverse suite of CNC-controlled equipment, each tailored for specific tasks and materials. Choosing the right machine—and the right machining technique—is critical to achieving the desired product quality, cost efficiency, and production throughput. Below, we break down the most common types of precision machining equipment and their respective roles in advanced manufacturing:

CNC Lathes and Turning Machines

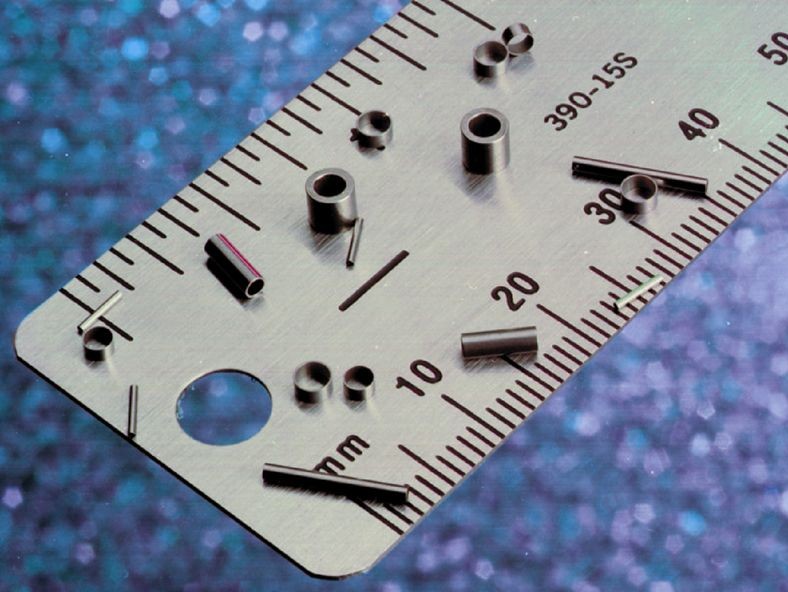

CNC lathes and turning centers rotate material stock while precisely controlled cutting tools remove material in a linear fashion. This method is ideal for producing cylindrical or conical shapes, such as shafts, bushings, and pulleys, with exceptional concentricity and surface finish. A subset of these machines, known as CNC Swiss lathes, is designed for ultra-precise, small-diameter parts. In Swiss-type lathes, the material both rotates and slides axially through a guide bushing, enabling tight tolerances on miniature and complex geometries—common in watchmaking, medical device manufacturing, and electronics.

CNC Milling Machines

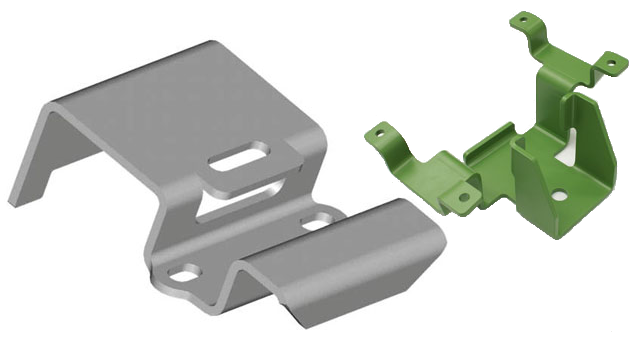

CNC milling machines are highly versatile tools capable of producing intricate 3D shapes, slots, pockets, and surfaces by rotating cutting tools against a stationary workpiece. These machines are indispensable for creating prismatic components with complex features, including brackets, enclosures, and custom mechanical assemblies. CNC milling companies often offer both vertical and horizontal milling capabilities, with multi-axis configurations (3-, 4-, or 5-axis) that enable the machining of parts from multiple angles in a single setup—dramatically increasing efficiency and reducing lead times.

CNC Laser Machines

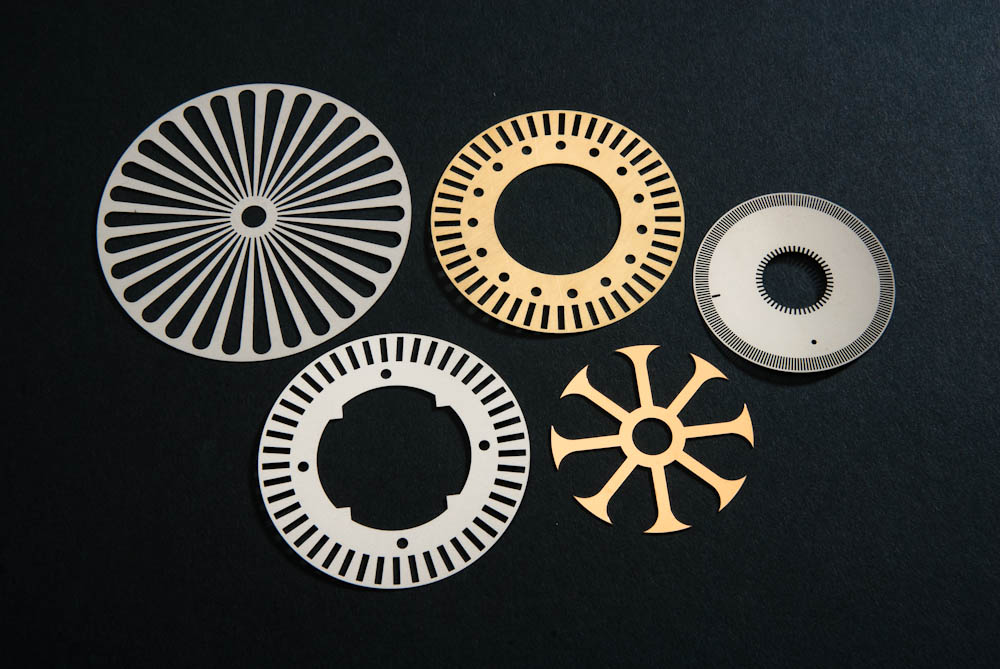

CNC laser cutting machines employ high-powered, focused laser beams to cut, engrave, or etch materials with extraordinary precision. The non-contact nature of laser machining makes it ideal for processing delicate materials, achieving narrow kerf widths, and creating highly detailed features. Common applications include sheet metal fabrication, electronics enclosures, signage, and custom gaskets. The laser’s heat melts or vaporizes the target material, and computer-controlled motion ensures repeatable, intricate patterning.

CNC Electrical Discharge Machines (EDM)

Electrical Discharge Machining (EDM) utilizes controlled electrical sparks to erode conductive materials into the desired shape. This process, also called spark eroding, wire EDM, or die sinking, is critical for producing complex internal geometries, sharp inside corners, and delicate features that would be difficult or impossible to achieve with conventional cutting tools. EDM is especially popular in mold-making, aerospace, and medical industries, where ultra-fine tolerances and smooth surface finishes are required.

CNC Plasma Cutting Machines

CNC plasma cutters harness a high-temperature plasma arc—reaching up to 50,000° F—to slice through electrically conductive materials like stainless steel, aluminum, copper, and brass. The intense heat melts the metal along the cut path, while high-velocity gas blows away the molten material. Plasma cutting is valued for its speed, cost-effectiveness, and ability to handle thick materials in industrial fabrication, automotive repair, and metal art applications. However, the process is best suited for projects where high precision is less critical than with laser or waterjet cutting.

Other Precision Machining Techniques

In addition to the above, the precision machining industry also relies on:

- CNC waterjet cutting: Uses high-pressure streams of water, sometimes mixed with abrasive particles, to cut a variety of materials without introducing heat-affected zones.

- Surface and cylindrical grinding: Delivers ultra-smooth finishes and tight tolerances for applications such as bearing surfaces, hydraulic components, and tooling.

- Micro machining: Involves producing extremely small, intricate parts for industries like microelectronics, dental implants, and miniature robotics.

- Multi-axis machining: Enables simultaneous movement along several axes, facilitating the creation of complex, organic, or contoured shapes with minimal setups.

Curious about which precision machining process best fits your project? See our guide to selecting the right machining partner and process below.

Applications of Precision Machining

Precision machining is foundational to a broad spectrum of industries and product categories, enabling innovation, operational efficiency, and product reliability. Common applications include:

- Repairing and restoring worn or damaged tools, components, and assemblies with exact-fit replacement parts.

- Manufacturing complex parts that must work together in assemblies—such as gears, housings, brackets, and fasteners—where exact alignment and fit are crucial for performance and safety.

- Producing critical medical devices and implants, from surgical tools and orthopedic implants to dental components and cardiovascular stents, requiring biocompatibility and absolute precision.

- Supporting the oil and gas sector with precision-machined pump housings, drill bits, valves, and high-pressure fittings, all designed to withstand harsh environments and rigorous operational demands.

- Enabling the hydraulics industry to produce piston heads, bolts, gears, and a variety of other components that demand high strength, tight tolerances, and smooth finishes for leak-free operation.

- Supplying the firearms industry with precisely machined equipment, including safety locks, suppressor baffles, triggers, and receivers, where performance and reliability are paramount.

- Empowering the aerospace and defense sectors with flight-critical parts—such as turbine blades, landing gear components, and avionics housings—that must meet stringent regulatory standards and endure extreme conditions.

- Enhancing consumer electronics manufacturing with heat sinks, connectors, and custom enclosures that support miniaturization and efficient thermal management.

- Facilitating renewable energy systems, including wind turbines and solar panel components, where durability and precision are key for long-term performance.

Want to learn more about how precision machining can accelerate your product development or production schedule? Discover key advantages and decision factors below.

Benefits of Precision Machining

Partnering with a skilled precision machining service provider brings a host of valuable benefits to your business, product, or project:

- Unmatched accuracy and repeatability: Achieve extremely tight tolerances—often within microns—ensuring all manufactured parts are dimensionally consistent and fit perfectly in assemblies.

- Enhanced design flexibility: Leverage advanced CNC capabilities to produce complex geometries, intricate patterns, and custom features that are difficult or impossible using traditional manufacturing methods.

- Superior quality and performance: Precision machining delivers parts with excellent surface finishes, sharp edges, and exceptional material properties—resulting in longer service life and lower maintenance costs.

- Material efficiency and cost savings: Subtractive processes minimize material waste by removing only what’s necessary, reducing raw material costs and promoting sustainability.

- Fast prototyping and rapid production: Digital workflows and automated setups allow for quick turnaround on prototypes, low-volume runs, or full-scale production, accelerating time to market.

- Customer-driven customization: Easily tailor parts to unique client requirements, allowing for product differentiation, improved functionality, and enhanced user experience.

- Reduced risk of defects and recalls: Automated quality control, in-process monitoring, and precise toolpath execution minimize the risk of errors, ensuring regulatory compliance and customer satisfaction.

- Scalability: Precision machining solutions can adapt to both small-batch and high-volume production needs, offering flexibility as your business grows.

Looking for a solution to your high-tolerance manufacturing needs? Find the right precision machining company with our expert guidance below.

Choosing the Right Precision Machining Company

With so many providers in the market, selecting the best precision machining partner for your project can be challenging. Consider these critical decision factors to streamline your search and ensure a successful outcome:

- Technical expertise: Does the company demonstrate deep knowledge of your industry’s requirements, material selection, and advanced machining methods such as 5-axis CNC, micro machining, or EDM?

- Equipment capabilities: Can the provider handle your part dimensions, complexity, and material type with the latest CNC technology and quality assurance processes?

- Quality certifications: Look for ISO 9001, AS9100, or relevant medical/aerospace certifications, which signal robust quality management systems and commitment to regulatory compliance.

- Production capacity and lead time: Does the company have the resources to meet your volume needs and strict deadlines, whether for fast prototypes or full-scale production runs?

- Customer service and communication: Responsive, transparent communication is vital for project success. Choose a provider that offers clear timelines, detailed quotes, and proactive updates.

- Cost competitiveness: Evaluate pricing models for transparency, value, and alignment with your project budget—while considering total cost of ownership, not just upfront price.

- Location and logistics: Consider whether a domestic or international supplier best matches your delivery, support, and intellectual property requirements.

To simplify your search, use our comprehensive >directory of precision machining companies. Each business profile details their experience, technical capabilities, certifications, and services. Easily contact providers for quotes or more information via our integrated contact forms. Our proprietary website previewer enables you to review company websites quickly and compare offerings at a glance. When ready, use our streamlined RFQ form to reach multiple precision machining businesses with a single request.

Still have questions? Consider these key topics as you evaluate your options:

- What are the most cost-effective precision machining solutions for your industry?

- How do you ensure quality control and traceability in CNC machining?

- Which materials are best suited for your application’s strength, durability, or biocompatibility requirements?

- What are typical lead times for prototype versus production orders?

- How can you transition from 2D drawings or legacy parts to digital CNC workflows?

- What value-added services (like finishing, assembly, or inspection) does the provider offer?

Whether you are an engineer, product designer, procurement manager, or entrepreneur, partnering with the right precision machining company can unlock new levels of innovation, quality, and efficiency for your products. Contact us today to discuss your requirements, request a quote, or schedule a consultation with an experienced machining expert.

Frequently Asked Questions About Precision Machining

- What is the difference between CNC machining and precision machining?

While all CNC machining is precise, the term "precision machining" specifically refers to processes that achieve extremely tight tolerances and high repeatability, often for mission-critical industries. - Which industries benefit most from precision machining?

Aerospace, automotive, medical device, electronics, defense, oil & gas, and industrial automation are among the top sectors relying on precision machining for product quality and regulatory compliance. - How do I choose the right material for my precision-machined part?

Material selection depends on the application’s strength, weight, corrosion resistance, biocompatibility, and cost requirements. Experienced machining companies offer guidance based on your specific needs. - Can precision machining handle both prototyping and mass production?

Yes. Modern CNC shops are equipped to handle everything from single prototypes to high-volume production runs, often with seamless scalability. - What quality certifications should I look for?

Look for ISO 9001, AS9100 (aerospace), ISO 13485 (medical), and ITAR registration, depending on your industry and product type.

If you’re ready to take the next step or need expert advice, request a precision machining quote or contact our team today for personalized assistance and solutions tailored to your project.

Broaching

Broaching CNC Machining

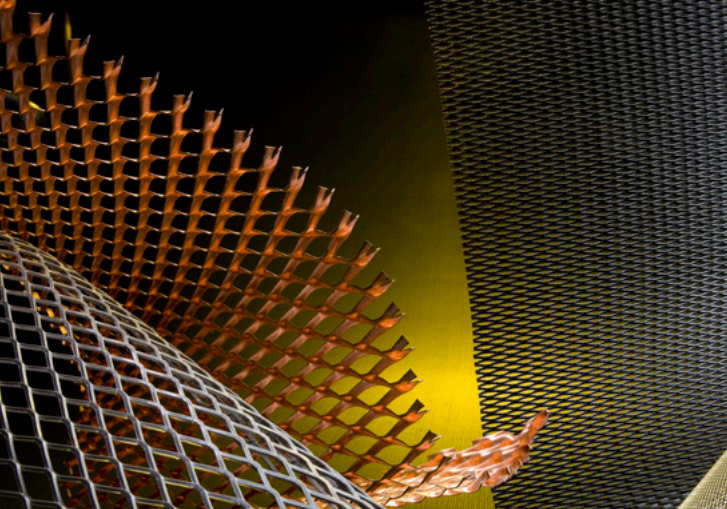

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

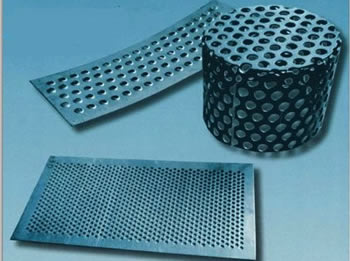

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

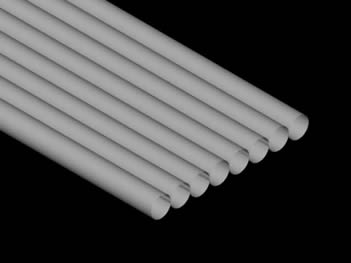

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services