CNC machine tools are all about repeatable precision. Once a prototype part has been thoroughly tested, the code created during prototype machining can be implemented in short-run to full long-run, continual production of identical, high quality precision parts. The CNC machine work can either be carried out in a single cell consisting of a combination of the different tools needed for the job, or sometimes a number of separate machines are used with humans or robots moving the component from machine to machine in the process of the particular cutting, milling, drilling, grinding, punching, etc. that is necessary, and finishing too! CNC programming instructs the positioning, pressure applied, depth and all other movements of these automated devices. Common materials that CNC machines work with include any number of metals, glass, ceramics, wood and plastics.

Because a part’s computer file can be saved for later use, CNC services are highly advantageous in manufacturing military, automotive and aerospace parts, and any other components that are produced over and over continually, as the code can be modified and streamlined for future upgrades as well.

Broaching

Broaching CNC Machining

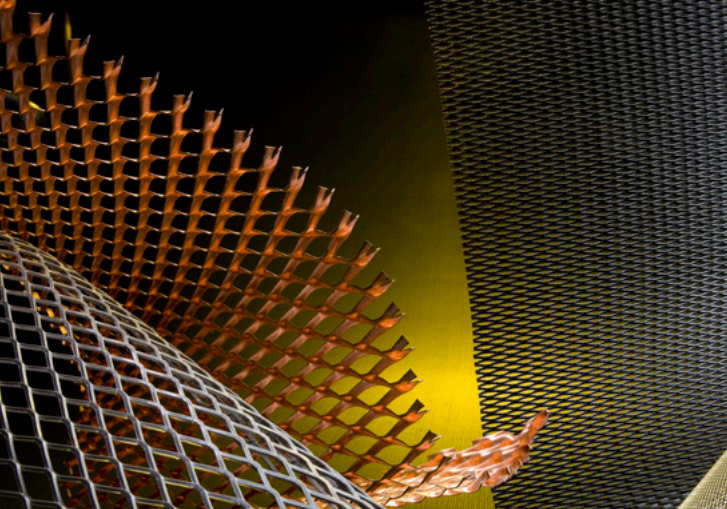

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

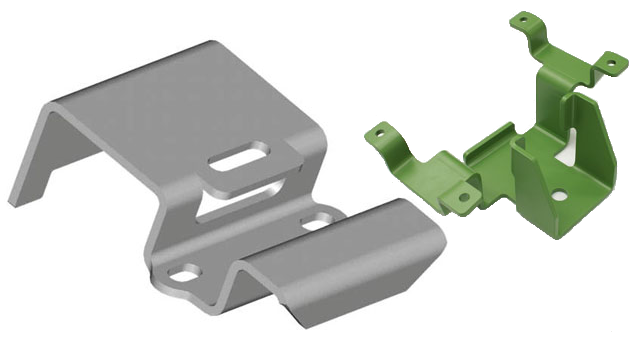

Metal Etching Metal Fabrication

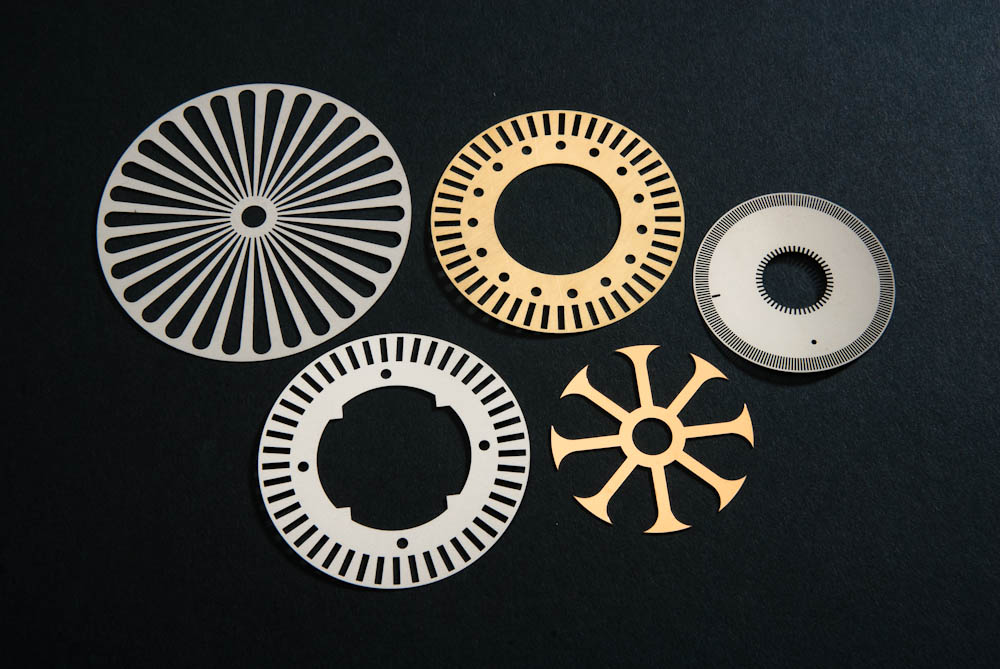

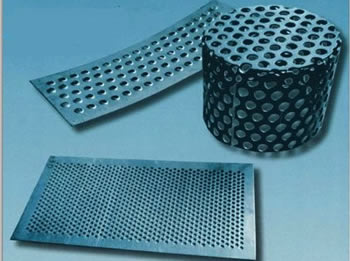

Metal Fabrication Perforated Metals

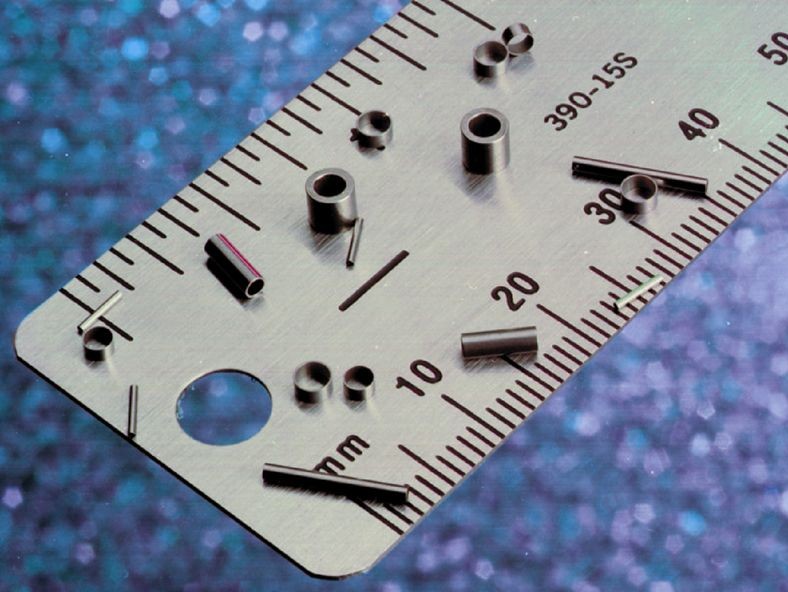

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services