Shamrock Precision USA

Shamrock Precision USARequest A Quote

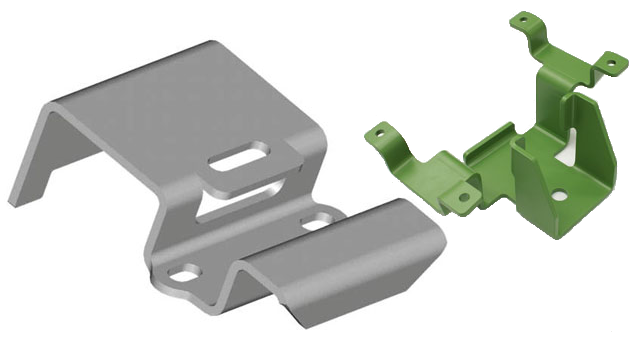

Dallas, TXAt Shamrock Precision USA, we specialize in delivering high-quality CNC machining services that meet the demanding specifications of industries across the board. With a focus on precision, consistency, and reliability, we have built our reputation on providing close-tolerance components for customers who depend on performance-critical parts. Our team operates with a deep understanding of advanced manufacturing processes, leveraging multi-axis CNC equipment to produce everything from simple turned parts to complex machined assemblies with tight dimensional tolerances. We work with a wide range of materials including stainless steel, aluminum, titanium, and high-performance alloys, allowing us to serve diverse markets such as aerospace, oil and gas, medical, and industrial automation. Our capabilities include CNC turning, milling, drilling, and threading, all supported by rigorous in-process and final inspections to ensure each part meets exact specifications. We take pride in our ability to deliver prototype quantities as well as high-volume production runs, all while maintaining the same level of precision and quality control. What sets us apart is our commitment to engineering support, responsive service, and continuous improvement. We collaborate closely with our clients to optimize part designs for manufacturability and cost-efficiency, often providing input that improves both performance and lead time. At Shamrock Precision USA, we don’t just machine parts—we build lasting partnerships through excellence in execution and a dedication to helping our customers succeed.

Leading CNC Machining Companies

More CNC Machining Companies

Additional Categories: Aluminum

Broaching

Broaching CNC Machining

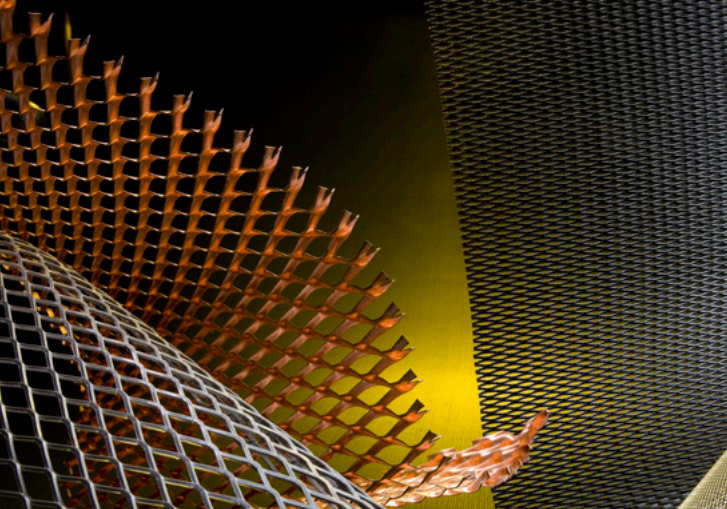

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

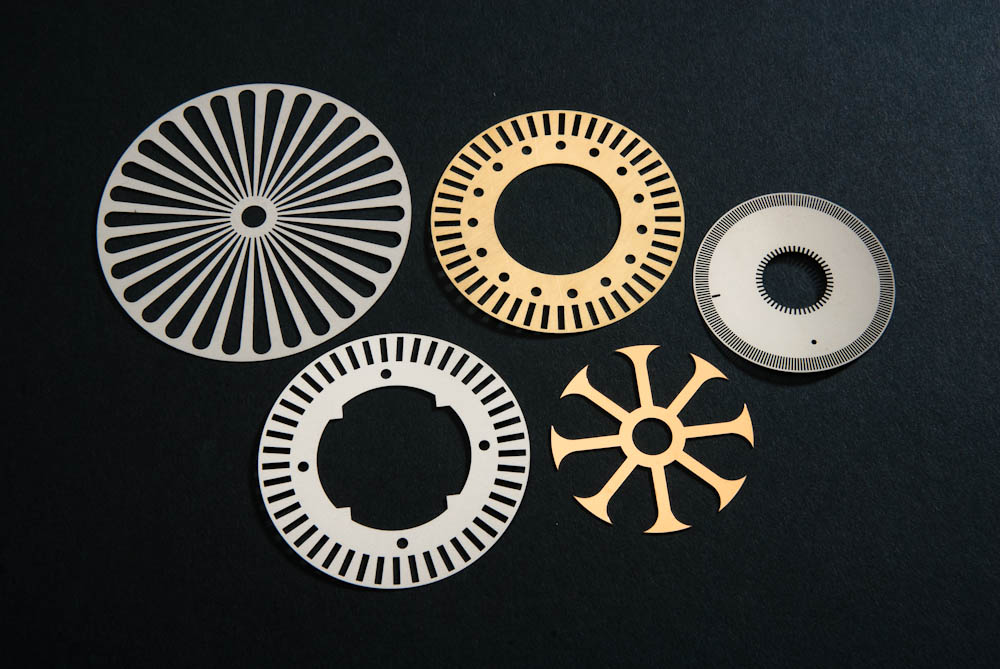

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

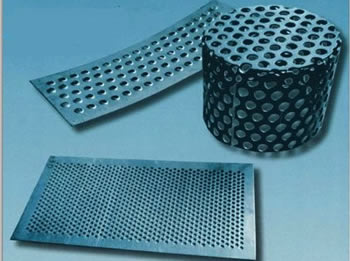

Metal Fabrication Perforated Metals

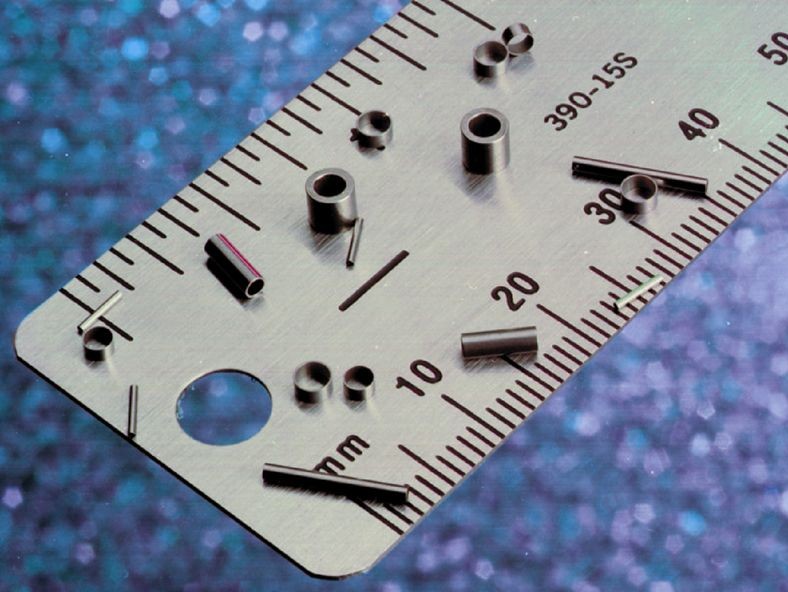

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services