Thuro Metal Products, Inc.

Thuro Metal Products, Inc.Request A Quote

Brentwood, NY | 800-238-3929Thuro Metal Products, Inc., based in Brentwood, New York, is a leading provider of Precision Metal Parts catering to many industries. With a strong commitment to quality and customer satisfaction, Thuro has established itself as a trusted partner in delivering precision-engineered solutions. Holding ISO 9001:2015 - AS9100D registration and ITAR certification, Thuro adheres to stringent quality standards and ensures compliance with the highest industry regulations. At Thuro Metal Products, we offer a comprehensive range of products, services, and capabilities tailored to meet the unique needs of our customers. Our extensive CNC Turning and CNC Milling capacity and capability allow us to efficiently serve any industry requiring Precision Component Parts and Assemblies. Our core capabilities encompass a range of advanced manufacturing processes, allowing us to produce intricate components and assemblies with exceptional precision. Thuro specializes in Complex Precision Assemblies, leveraging our expertise in meticulous engineering and assembly techniques to deliver reliable and high-performance solutions to our customers. With our state-of-the-art facilities and cutting-edge technology, we provide a range of precision machining services. Our CNC Swiss Turning Services enable us to produce intricate and complex parts with superior accuracy and efficiency. Utilizing advanced Multi-Spindle Machining techniques, we can achieve high production volumes while maintaining strict quality control. Thuro Metal Products boasts expertise in CNC Milling, utilizing advanced computer numerical control technology to achieve precise and repeatable results. Our CNC Turning capabilities further enhance our production capabilities, enabling us to manufacture components with exceptional dimensional accuracy and surface finish. Flexibility is at the core of our operations, and we cater to both high and low volume production requirements. Whether you need a small batch of specialized components or a large-scale production run, Thuro Metal Products has the capacity and expertise to meet your demands. Our team of highly skilled engineers, machinists, and technicians is dedicated to delivering excellence in every project we undertake. We work closely with our clients, providing personalized attention and support throughout the manufacturing process. Our commitment to continuous improvement and investment in the latest technology ensures that we stay at the forefront of the industry, delivering innovative solutions that exceed expectations. Choose Thuro Metal Products, Inc. for your precision metal part needs, and experience the unmatched quality, precision, and reliability that sets us apart. We are proud to be the trusted partner of choice for businesses seeking exceptional products and services to drive their success in today's competitive market.

Broaching

Broaching CNC Machining

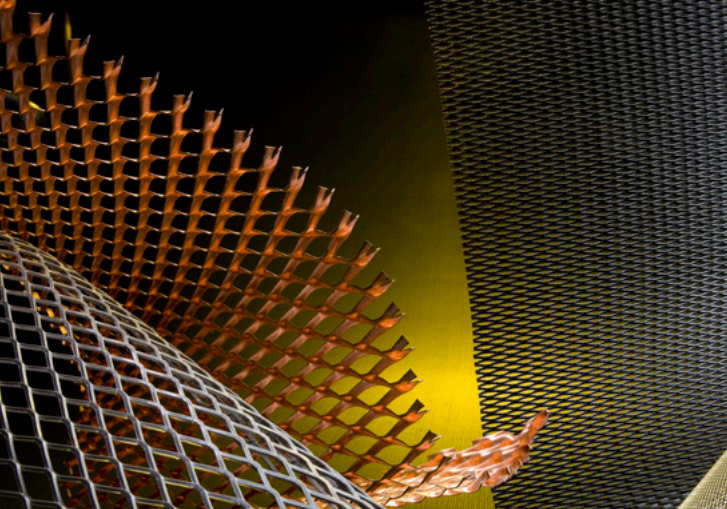

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

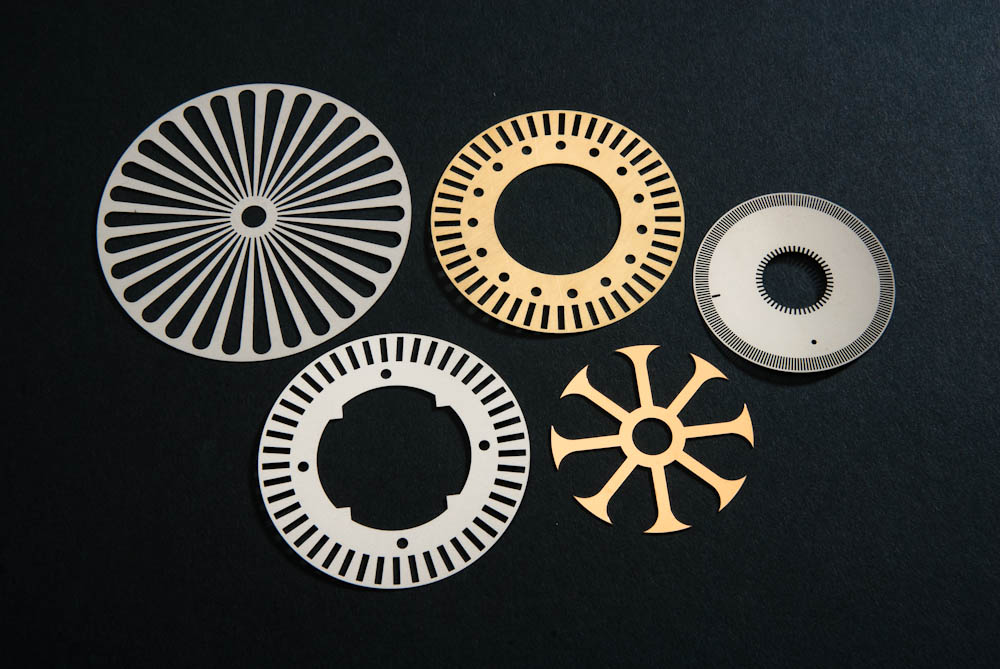

Laser Cutting Metal Etching

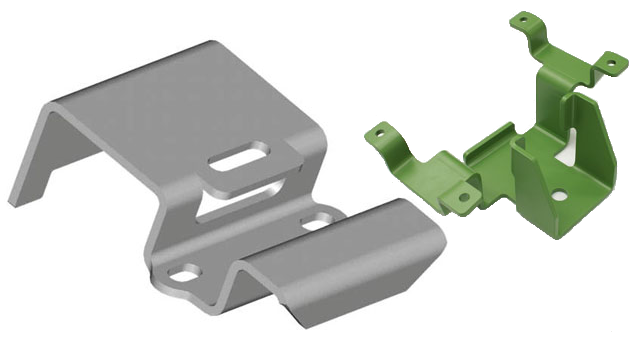

Metal Etching Metal Fabrication

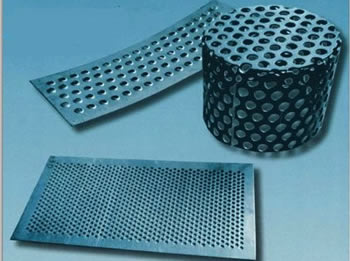

Metal Fabrication Perforated Metals

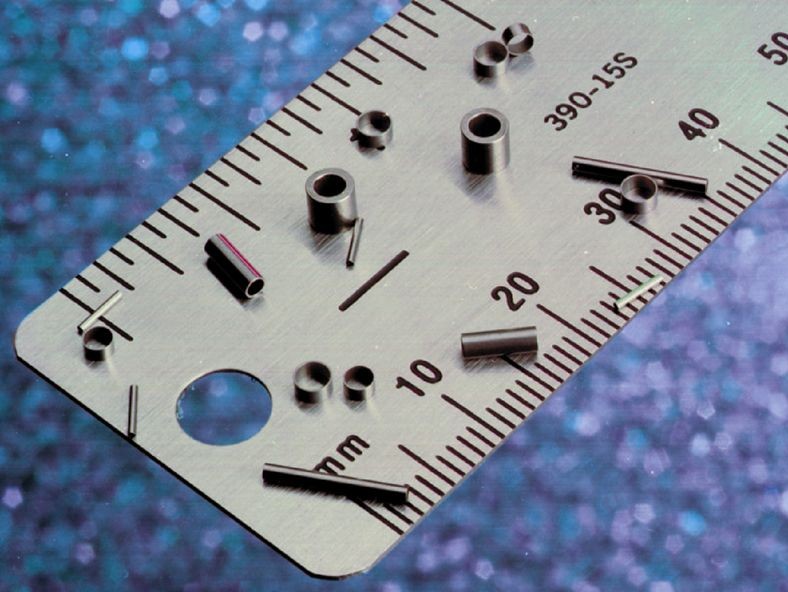

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services