5 Axis CNC Machining

The normal functioning of CNC machines is done along the three Z, X, and Y axes. The five axes machines have two more axes accessible, which are namely A and B. The addition of the two extra axes makes it easy to cut complex and intricate parts…

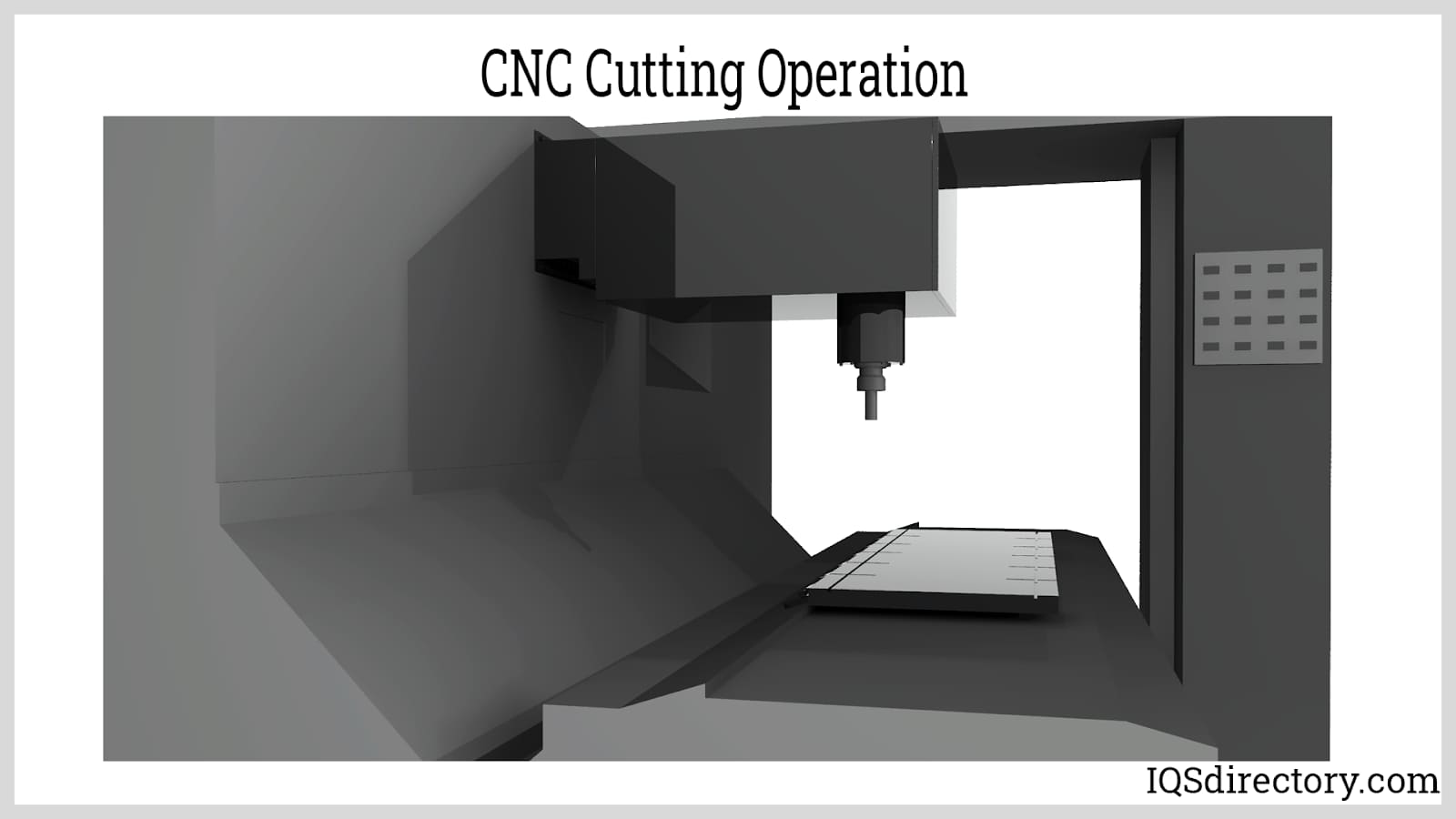

CNC Machining

CNC machining is an electromechanical process that manipulates tools around three to five axes, with high precision and accuracy, cutting away excess material to produce parts and components. The initial designs to be machined by CNC machining are created in CAD…

CNC Milling

The CNC process was developed in the 1950‘s and took a leap forward in the 1980‘s with the addition of computerization. Unlike other production processes, CNC begins with a rendering by a computer, which creates a two or three dimensional representation of the part to be produced…

G-Code

G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn‘t necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a CNC machine on how to complete a process…

M-Code

Computer numerical control (CNC) is a fundamental part of modern manufacturing. The majority of machines operate using instructions and guidelines that have been downloaded using a CNC program controller…

Types of Machining

Machining is a manufacturing process used to produce products, parts, and designs by removing layers from a workpiece. There are several types of machining that include the use of a power driven set of machining tools to chip, cut, and grind to alter a workpiece to meet specific requirements…

What is CNC Machining?

Computer Numerical Control (CNC) refers to a sophisticated manufacturing process where programmed software directs the operations of factory machinery. This method is integral in managing various intricate machines, such as grinders, lathes, mills, and…

Additive Manufacturing (AM)

Additive manufacturing (AM) or additive layer manufacturing (ALM) is a three-dimensional printing process that produces components and parts by adding layers of material to fabricate physical renderings of computer designs. The multiple layers of additive

Automatic Screwdrivers

An automatic screwdriver is a piece of equipment that automatically inserts screws into a product during assembly and production. Since every production operation is unique and requires a different type of automatic screwdriver system, the sizes, designs, capabilities, and configurations…

Contract Manufacturing

Contract manufacturing is a business model where a company hires a manufacturer to produce its products or components. It is an outsourcing method for producing products by taking advantage of the resources and expertise of…

Metal Fabrication

Metal fabrication is the process of turning sheet metal and other flat metals into predetermined forms. The process begins with sheet metal no thicker than a quarter inch. The metal is malleable enough to take on various shapes at…

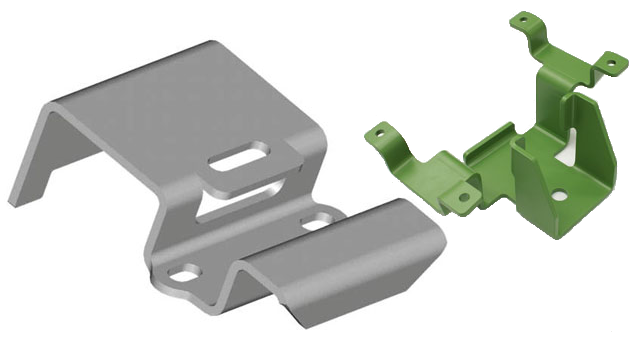

Sheet Metal Fabrication

Sheet metal fabrication is metal that has been formed into thin and flat sheets which is then cut and bent into various shapes. Different metals, brass, steel, copper, tin, titanium, aluminium, etc., can be made into sheet metal…

Broaching

Broaching CNC Machining

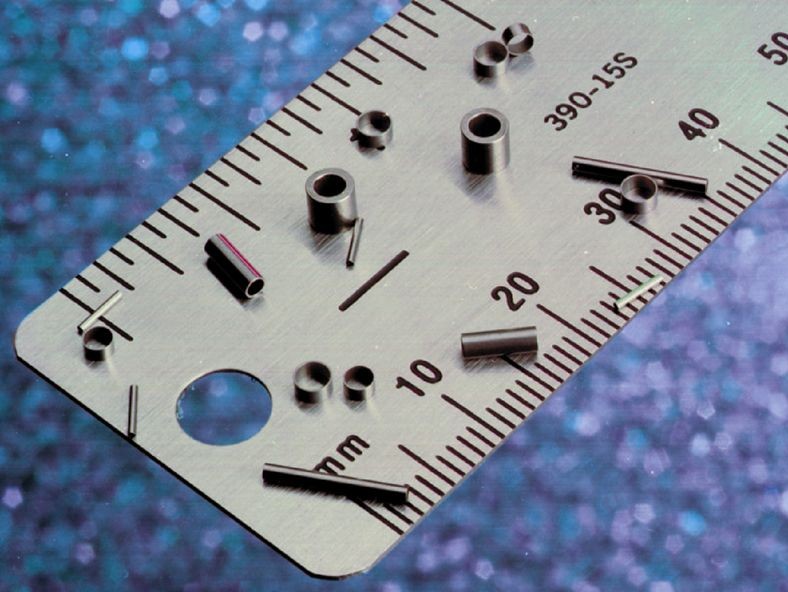

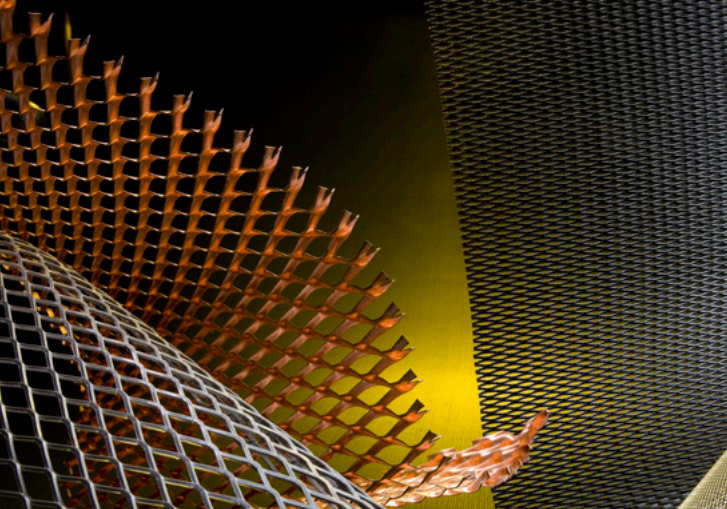

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

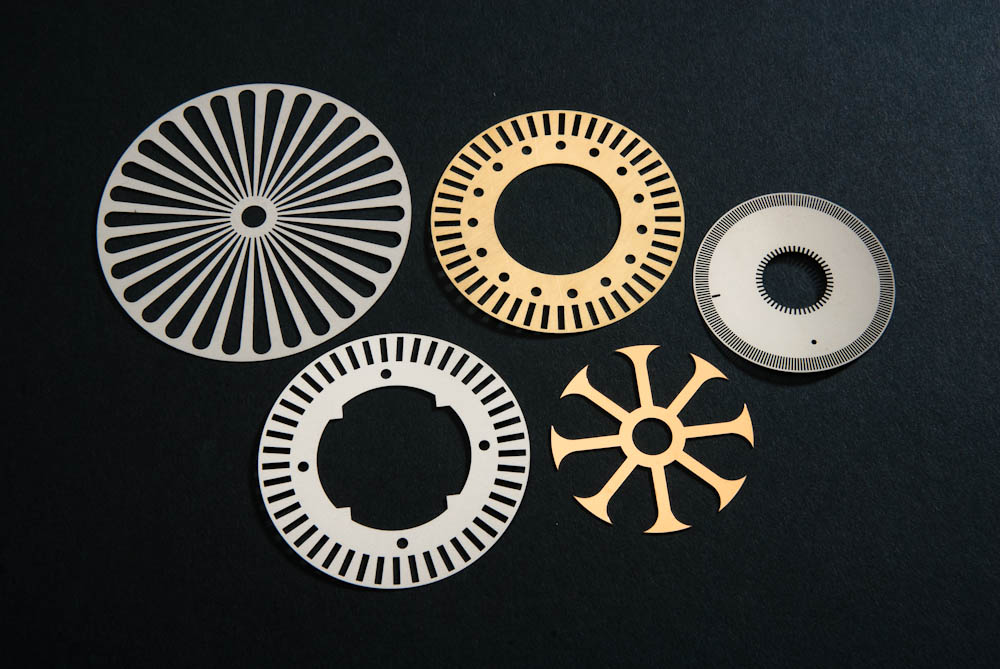

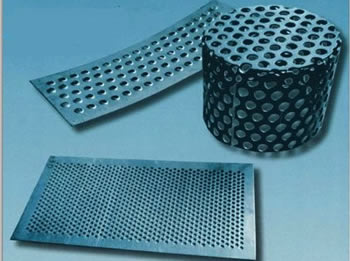

Metal Fabrication Perforated Metals

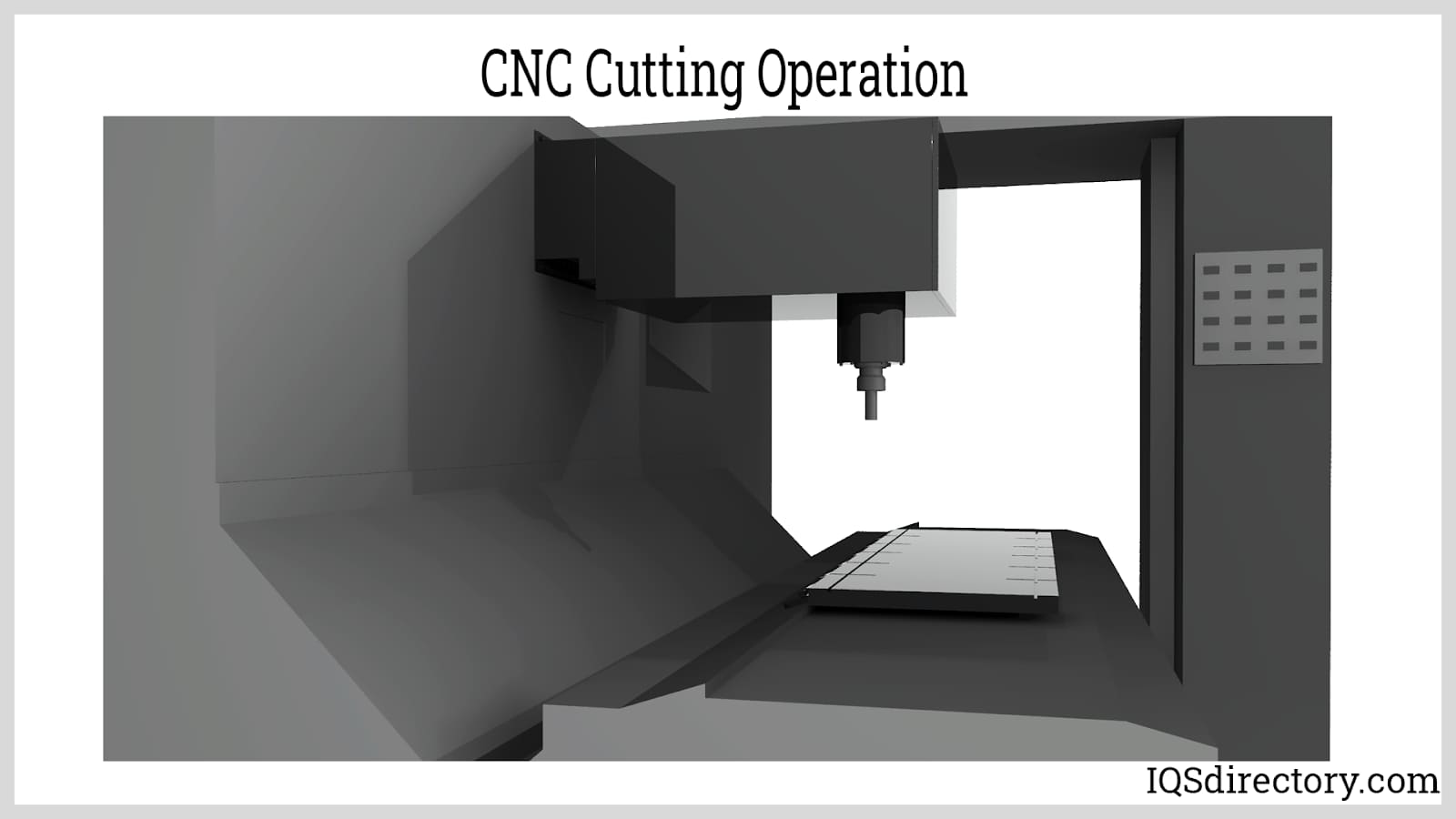

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

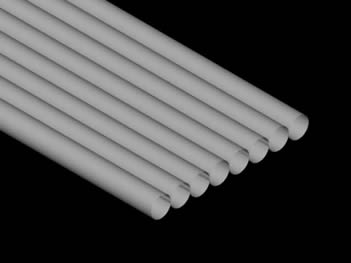

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services